High-Precision Steel Rule Blades for Packaging, Printing, Corrugated & Label Cutting

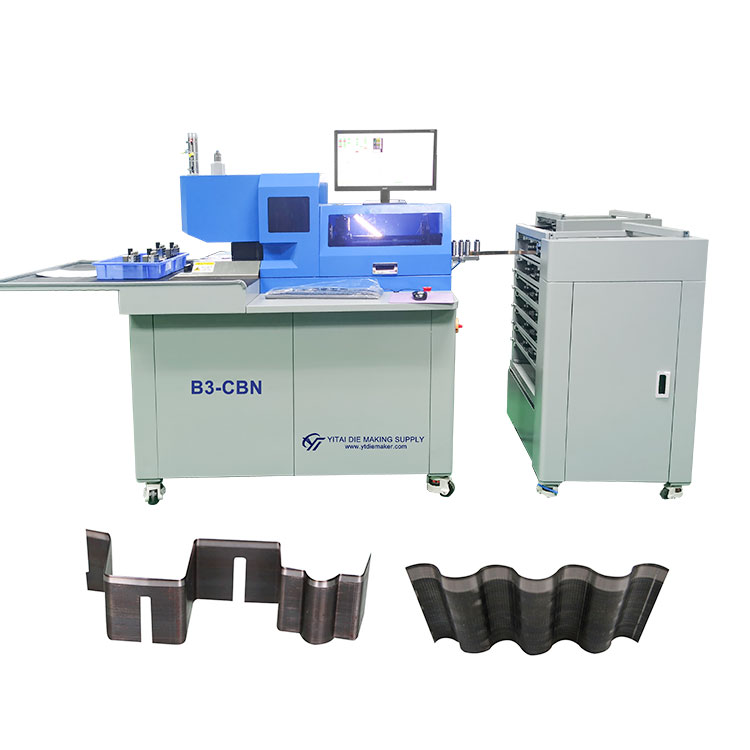

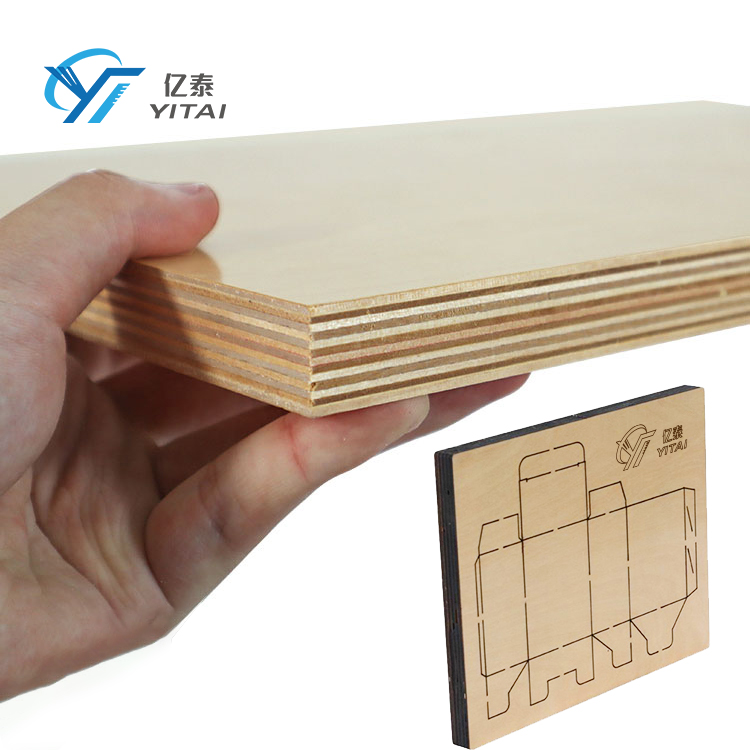

Flat cutting rules and creasing rules are core components in steel-rule die manufacturing, used extensively in packaging, printing, corrugated box production, labels, and various non-metallic material processing.

Choosing the correct rule type—cutting rules, creasing rulers, steel cutting rule, or a full cutting and creasing rule combination—directly affects cutting quality, creasing accuracy, and die service life.

YITAI provides a full range of steel rule blades, including 2pt steel rule, 3 point steel rule, center bevel steel rule, and custom blade profiles designed specifically for custom steel rule die production.

1. Understanding Flat Cutting Rules & Steel Rule Blades

Flat cutting rules (also known as steel rule blades for cutting dies) are manufactured from high-carbon or alloy steel and processed through quenching and anti-decarburization treatment.

This ensures high hardness, durability, and flexibility for bending on a steel rule die bender.

They are widely used for:

- Creasing rule cutting and creasing lines

- Corrugated board die cutting

- Paper & carton cutting

- Label and adhesive material cutting

- Electronics and insulation material processing

Blade Height (Creasing Rule Height & Cutting Rule Height)

YITAI provides standard and non-standard heights for both cutting rules and creasing rules:

- Non-standard blades: 7mm, 8mm, 9.5mm, 12mm

- Standard steel rule height: 22.9mm, 23.3mm, 23.6mm, 23.8mm

- Tall blades: 30mm, 35mm, 40mm, 50mm

Creasing rule height is selected according to paper thickness, corrugated flute type, and carton structural requirements.

Blade Thickness (Creasing Rule Thickness & Cutting Rule Thickness)

- 0.45mm (1.27PT) — adhesive labels

- 0.53mm (1.5PT)

- 0.71mm (2PT / 2pt steel rule)

- 1.07mm (3PT / 3 point steel rule)

- 1.42mm (4PT)

Thickness selection depends on bending difficulty, required pressure, and the structural complexity of the custom steel rule die.

2. Hardness Standards (Tip & Body Hardness)

Tip Hardness: HS50, HS52, HS55, HS72, HS76, HS78, HS80

Body Hardness: HS48–HS55

A harder tip maintains sharpness and cutting stability, while the softer body allows smooth bending on 2pt 3pt rules used in rotary and flat dies.

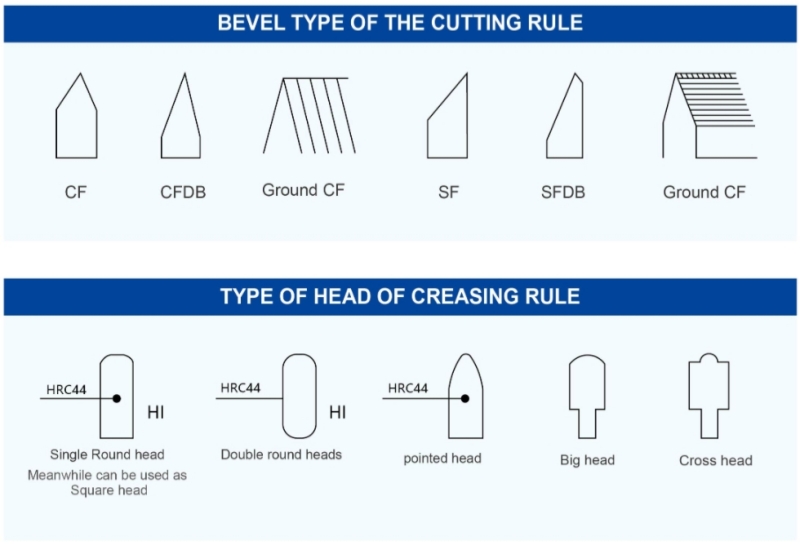

3. Blade Edge Types (Bevel Options)

YITAI offers multiple bevel types for both cutting and creasing applications:

Center Bevel Steel Rule (CB)

– Single bevel, suitable for general cutting jobs

– Ideal for corrugated, carton & folding box industry

Long Center Bevel (LCB)

– Double bevel, sharp & efficient

– Enhanced peak for clean cuts

Side Bevel (SB / LSB)

– Used for single-direction cutting

– Popular for high-volume, thin-paper jobs

Bevel Angles Available:

30°, 42°, 45°, 52°

- 30°: Very sharp, lower pressure tolerance

- 42°: Balanced & most widely used

- 52°: High durability for harder materials

4. Minimum Bending Angle (Rule Bending Performance)

- Recommended minimum bending angle: 20°

- Lower angles require slightly softer hardness for bending without cracking

This performance is critical when forming complex shapes using a steel rule die bender.

5. Standard Steel Rule Blade Stock Sizes (Packaging & Specs)

| Size | Packing | Volume & Weight |

|---|---|---|

| 2pt 0.71 × 23.80 × 1000mm | 100 pcs / box / 100m coil | 36×470×500mm / 15kg |

| 3pt 1.07 × 23.80 × 1000mm | 70 pcs / box / 70m coil | 36×470×500mm / 15kg |

| 4pt 1.42 × 23.80 × 1000mm | 50 pcs / box / 50m coil | 36×470×500mm / 15kg |

Suitable for stocking in large-volume steel rule die blade stock inventories.

6. Blade Variants (For Cutting, Creasing, Perforating & Special Applications)

YITAI manufactures a full range of cutting rules and creasing rules:

- Mirror Finish Blades — clean & smooth cutting

- Ground Edge Blades — higher precision

- Creasing Rules — for perfect folding lines

- Adhesive Blades — label and sticker cutting

- Perforation Blades — tear-line production

- Toothed / Serrated Blades — special effects

- Wavy Blades — decorative cuts

- Rule for Creasing Die — stable for corrugated boards

Industry Applications

Our cutting and creasing rules are widely used in:

- Packaging & Carton Manufacturing

- Corrugated Box Factories (E-flute, B-flute, C-flute)

- Commercial Printing & Post-Press Finishing

- Label Die Cutting

- Electronics & Insulation Material Cutting

- Custom Steel Rule Die Production

Why Using the Right Cutting or Creasing Rule Matters

Choosing the correct cutting rules, steel cutting rule, or creasing rule cutting configuration ensures:

- Cleaner, sharper cuts

- Accurate folding lines

- Reduced rework and downtime

- Longer rule lifespan

- Stable performance in high-speed die presses

- Improved die-cutting efficiency

YITAI – Your Reliable Supplier for Cutting Rules & Creasing Rules

YITAI provides a complete range of flat cutting rules, creasing rules, cutting and creasing rule combinations, and steel rule blades for cutting dies, serving die makers around the world with consistent quality and customization.

If you need:

✓ Custom hardness

✓ Special bevel angles

✓ Non-standard creasing rule height or thickness

✓ Custom steel rule die profiles

We can manufacture according to your drawings or samples.