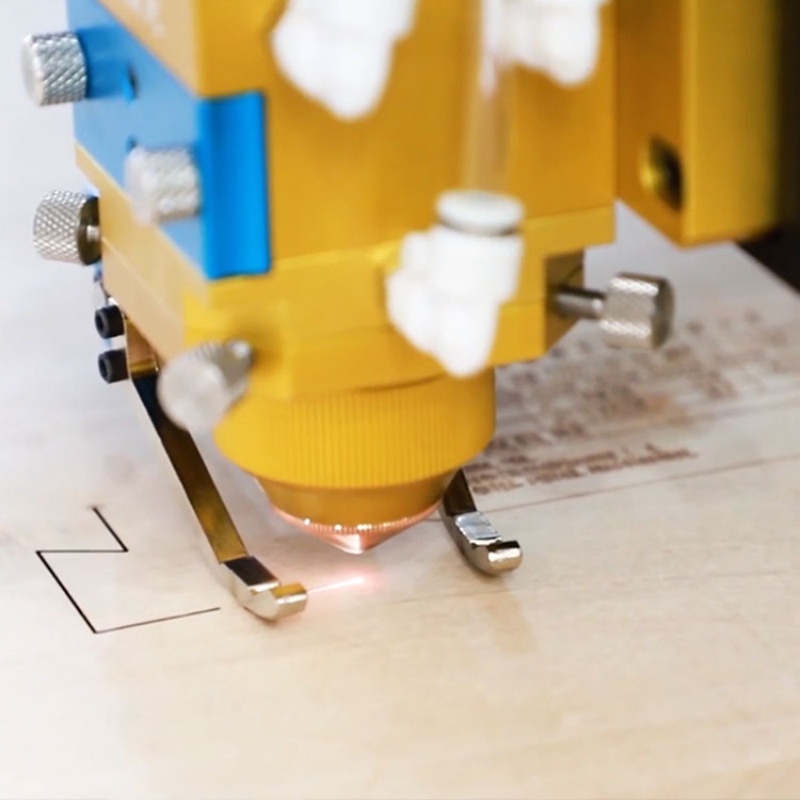

Key Features of the Cross Table Laser Cutting Machine

The YITAI Cross Table Laser Cutting Machine is engineered specifically for professional die-making, offering exceptional accuracy, stable performance, and a compact structure ideal for modern die shops and packaging plants. Designed for wooden die board cutting and electronic precision dies, this machine is built to deliver consistent, high-quality production.

Cross Table Laser Die Cutting Machine

1. Cross Table Structure for Stability & Compact Footprint

The cross table moving system ensures excellent cutting stability while minimizing the machine’s overall footprint — a perfect solution for factories with limited space but demanding high accuracy.

2. Advanced CO₂ Sealed Laser Tube

Equipped with a water-cooled, high-quality CO₂ sealed laser tube, the machine integrates seamlessly with a precision CNC mechanical drive system.

This combination guarantees long-term stability for:

- Wooden die board cutting

- Electronic component die-making

- Fine contour cutting tasks

3. Fixed Optical Path for Consistent Accuracy

By using a split-type fixed optical path structure, the system eliminates the optical deviation commonly seen in high-power laser machines.

This ensures:

- Uniform cutting quality

- High accuracy across the full working range

- Stable beam quality during long-term operation

4. Smart Exhaust System & Low Energy Consumption

The innovative smoke exhaust system keeps the working area clean and safe.

With its 220V external power supply and instant start-up, the machine offers:

- Low energy consumption

- No warm-up time

- Reduced production downtime

5. Wide Material Compatibility

Ideal for cutting:

- 15–23 mm plywood die boards

- PVC board

- Acrylic / organic glass

Available cutting line widths include 0.45mm, 0.71mm, 1.05mm, and 1.42mm, covering all common flat-die requirements.

6. Easy-to-Use Software Compatibility

Supports industry-standard design software:

- AutoCAD

- CorelDRAW

- Adobe Photoshop

Operators can easily create, edit, and optimize cutting paths for efficient production.

7. Precision Cutting Line Calibration

The built-in calibration system allows straightforward adjustment, ensuring:

- High-definition cutting lines

- Accurate kerf width

- Consistent performance

Technical Parameters

| Item | Specification |

|---|---|

| Model | YT46C-40/60 |

| Table Movement | Cross Table |

| Laser Power | CO₂ Sealed Laser Tube |

| X-Axis Travel | 1200 mm |

| Y-Axis Travel | 1600–1800 mm |

| Cutting Precision | 0.01 mm |

| Re-positioning Accuracy | ≤ 0.02 mm |

| Cutting Widths | 0.45 / 0.71 / 1.05(1.07) / 1.42 mm |

| Avg. Cutting Speed | 20–28 m/h |

| Transmission System | HIWIN Ball Screw + Linear Guide |

| Driving System | Yaskawa High-Precision Servo Motors |

| Machine Dimensions | 3800 × 2300 × 1600 mm |

| Gross Weight | 2000 KG |

| Laser Gas | CO₂ (99.99%) |

| Cutting Thickness | 1–22 mm |

| Centrifugal Blower | 1 set |

| Power Consumption | 4–5 kW/h |

Ideal Applications

- Flat wooden die board production

- Electronic component die cutting

- Packaging and printing industries

- High-precision sample making and prototyping

Certificate & Accuracy Testing

(YITAI equipment undergoes laser meter accuracy testing, ensuring moving tolerance within 0.02 mm for professional die-making standards.)

Our Services

- English-speaking engineer support for installation and training

- One-stop die-making equipment & materials supply

- English software, installation manuals, and training videos

- Low maintenance cost with full customer-oriented service

- 1-year warranty + lifetime engineering support

Before Quotation, Please Let Us Know:

- Which machine model you need

- What materials you will cut (size & thickness)

- Your business type — end user or distributor

Contact Us

YITAI provides a full line of die-making machines, tools, and consumables for global diemakers and packaging factories.

If you need assistance choosing the right machine, feel free to contact our professional team — we will help you find the best solution.