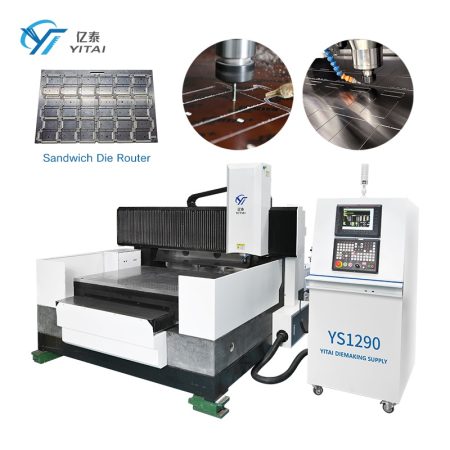

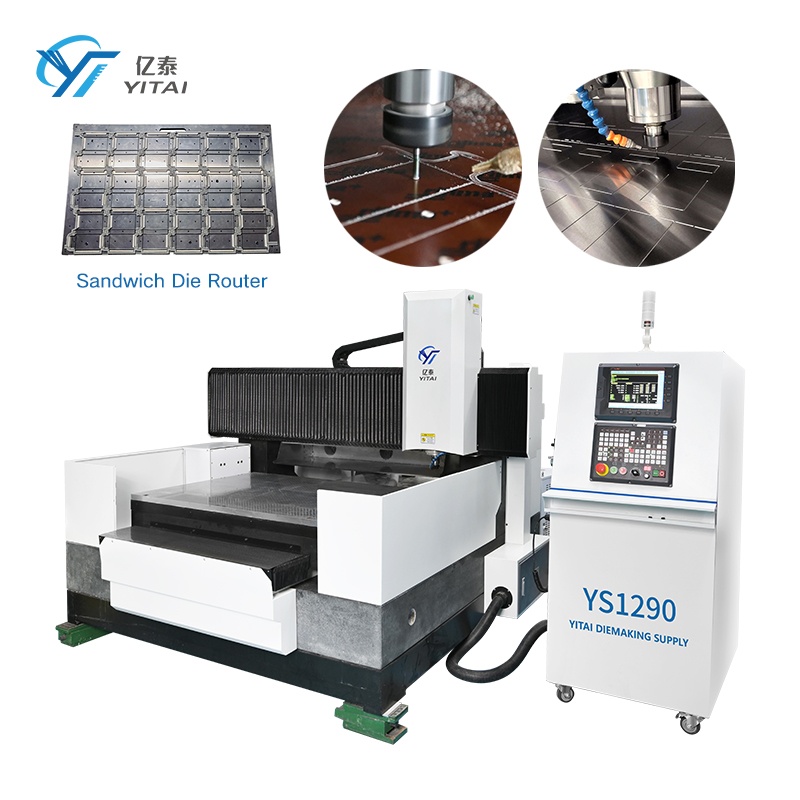

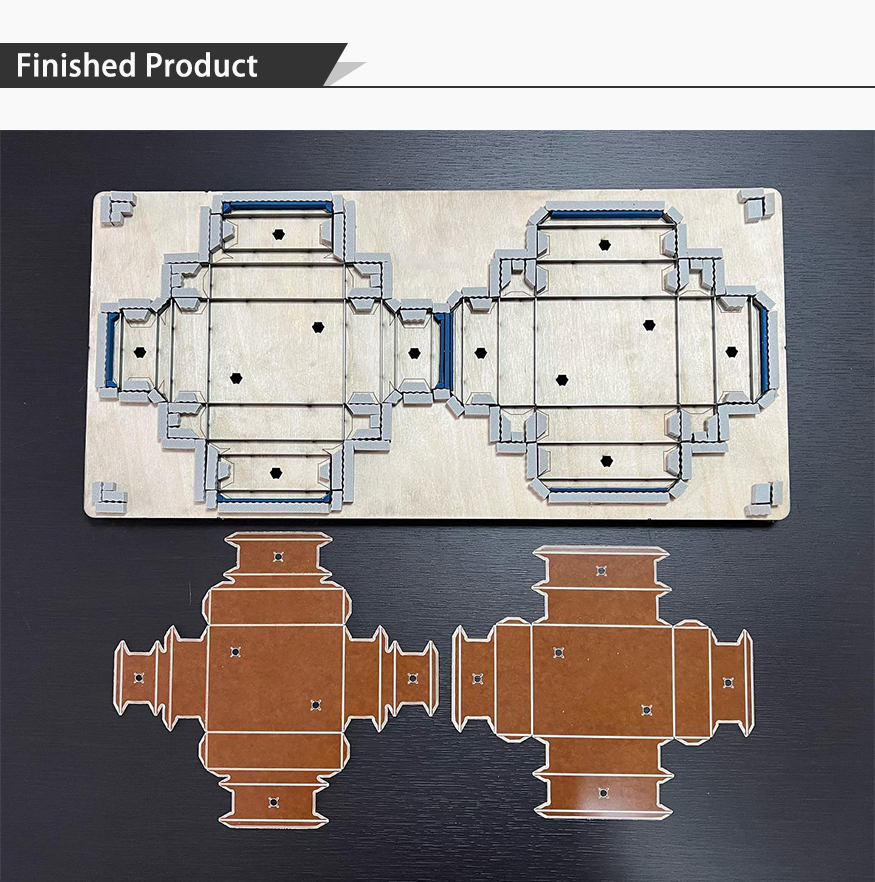

In the sandwich cutting die manufacturing process, machining accuracy, slot consistency, and long-term stability are critical factors that directly affect die performance and service life.

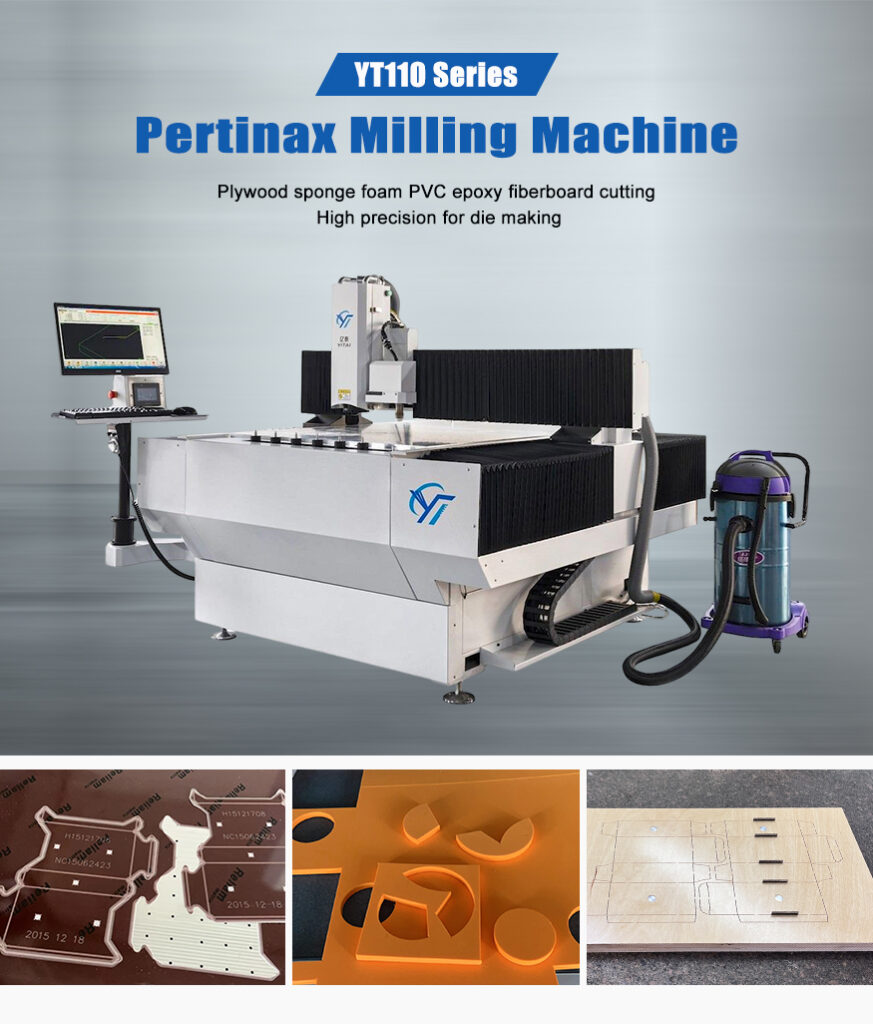

The YT110 CNC Pertinax Milling Cutting Machine is specifically developed for high-precision machining of Pertinax boards used in sandwich dies, while also supporting sponge and wood board processing.

Based on practical die-making applications, YT110 integrates the functions of traditional pertinax milling, and partially replaces water jet and laser cutting in specific processes, providing a more stable and controllable mechanical cutting solution.

Application Scope

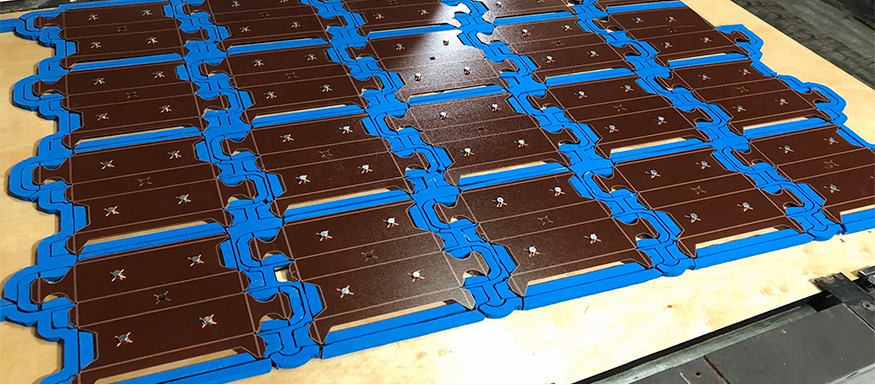

The YT110 is designed primarily for the sandwich cutting die industry, and is suitable for:

- Pertinax board cutting for laminated / sandwich dies

- Sponge cutting for stripping systems

- Wood board processing for die structures

- Edge milling of stripping dies

Its mechanical milling structure ensures high dimensional accuracy and repeatability, especially for applications requiring tight tolerances and clean slot geometry.

Key Features & Technical Advantages

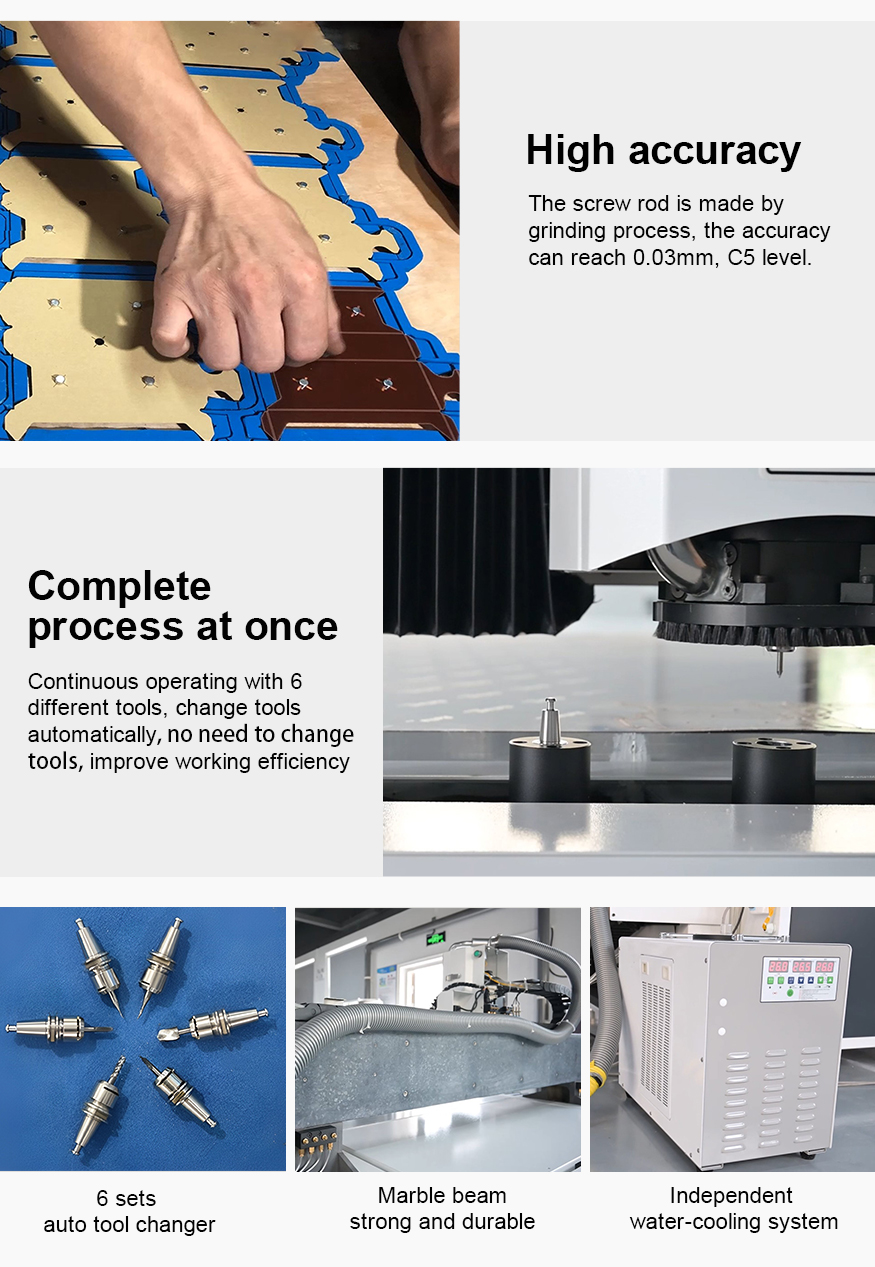

High-Efficiency Machining

- No-load speed up to 10 m/min, improving production efficiency in batch processing

- Stable performance suitable for continuous operation

High-Precision Transmission System

- Precision ground ball screw

- Positioning accuracy up to 0.03 mm (C5 grade)

- Re-positioning accuracy up to 0.01 mm

High-Speed Spindle System

- Spindle speed up to 60,000 RPM

- 2.5 kW spindle power

- Low vibration, stable output, and long service life

- Spindle tolerance controlled within < 0.003 mm

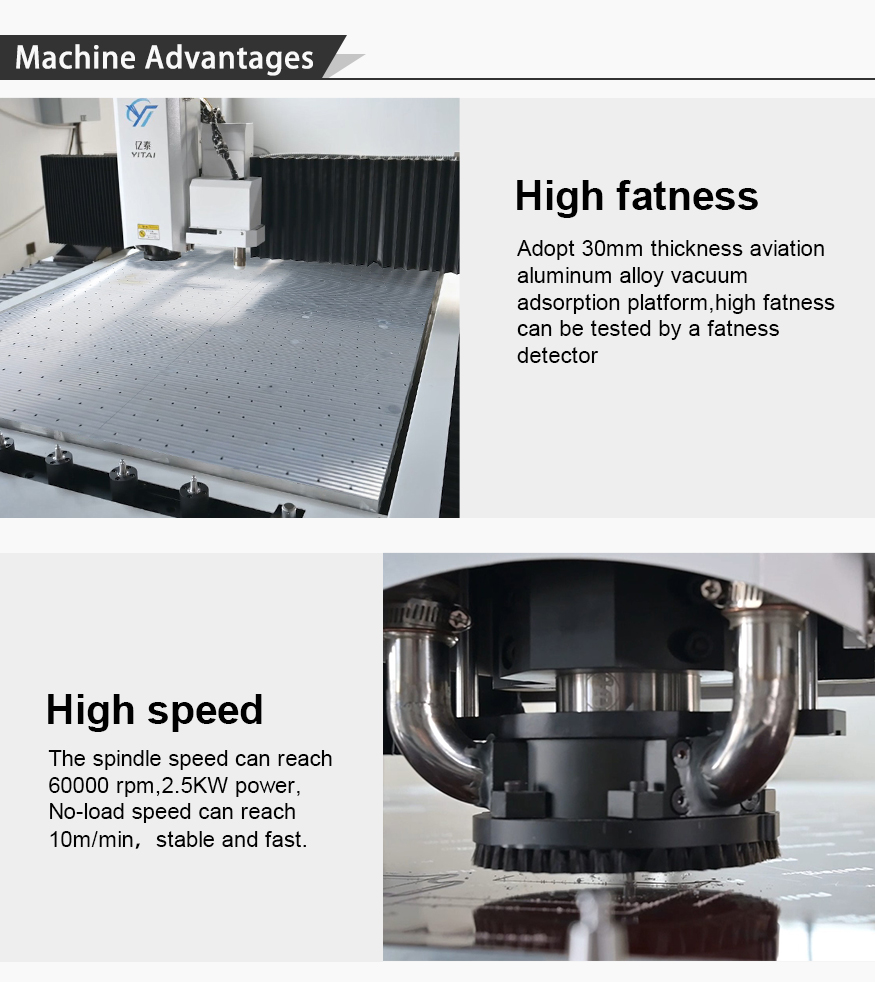

Flat and Stable Working Table

- High flatness table structure

- Flatness can be verified using professional flatness detection equipment

- Ensures consistent cutting depth and slot quality

Automatic Tool Changing

- Equipped with 6 sets of automatic cutter exchangers

- Enables multi-step machining in a single setup

- Reduces manual intervention and improves machining consistency

Machine Specifications

| Parameter | Specification |

|---|---|

| Model | YT110 |

| X-axis Travel | 1100 mm |

| Y-axis Travel | 1080 mm |

| Z-axis Travel | 90 mm |

| No-load Speed | 10 m/min |

| Cutting Precision | 0.02 mm |

| Re-positioning Precision | 0.01 mm |

| Spindle Speed | 60,000 RPM |

| Spindle Tolerance | < 0.003 mm |

| Cutting Thickness | Flat plywood 18 mm / PVC 6 mm / Sponge 7 mm |

| Power Supply | 380V / 6 kW (Three-phase) |

| Gross Weight | 2200 kg |

| Overall Dimensions (L×W×H) | 1600 × 1800 × 1400 mm |

Why Choose YT110 for Sandwich Die Manufacturing

Compared with laser or water jet cutting, mechanical milling offers better control over:

- Slot verticality

- Depth consistency

- Edge quality

- Long-term dimensional stability

YT110 is particularly suitable for die makers who prioritize precision, repeatability, and structural reliability in sandwich cutting dies, especially for high-speed die-cutting applications.

About YITAI

YITAI is a professional manufacturer and supplier of die-making machinery and equipment for the packaging industry.

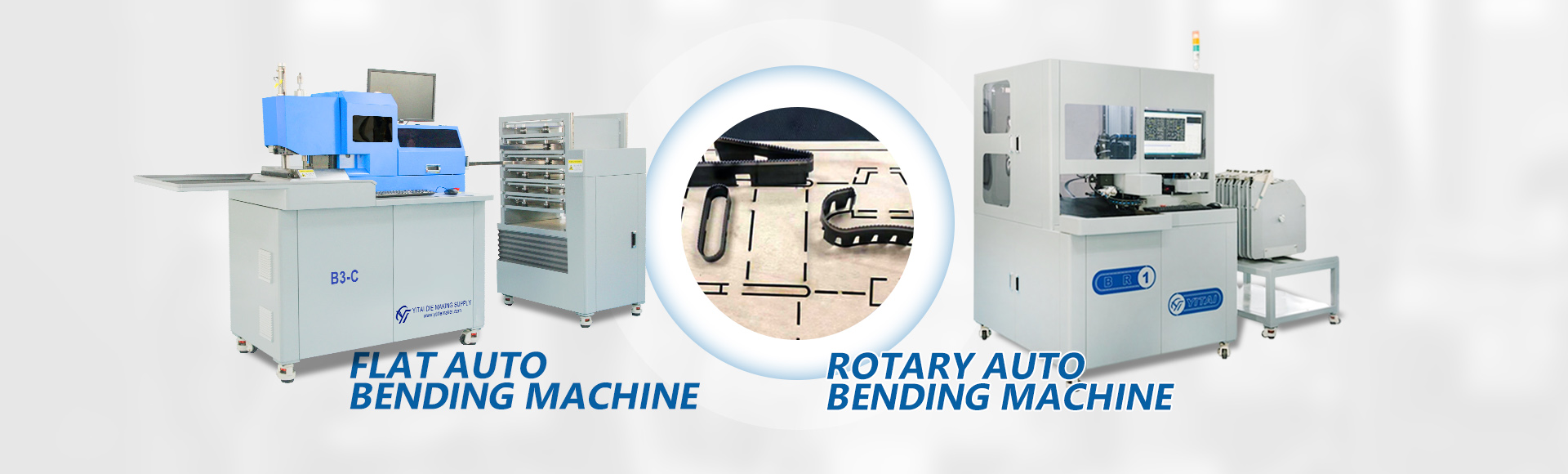

We specialize in the development and production of:

- CNC laser cutting machines

- Auto bender machines

- Creasing and cutting machines

- CNC milling solutions for die boards

YITAI machines have been exported to more than 100 countries worldwide, serving die makers and packaging manufacturers with diverse production requirements.

All YITAI machines are supplied with CE certification and Certificate of Origin (CO), ensuring compliance with international standards.

Our Service & Support

- English-speaking engineers available for installation and training

- One-stop die-making equipment and material supply

- English software, manuals, and training videos provided

- Low maintenance and repair cost with customer-oriented service support

- 1-year warranty and lifelong technical service

Technical Consultation

To recommend the most suitable configuration, please let us know:

- Which machine model you are interested in

- Materials to be processed (type, size, and thickness)

- Your business scope (end user or distributor)

Our technical team will assist you in selecting the optimal solution for your production needs.