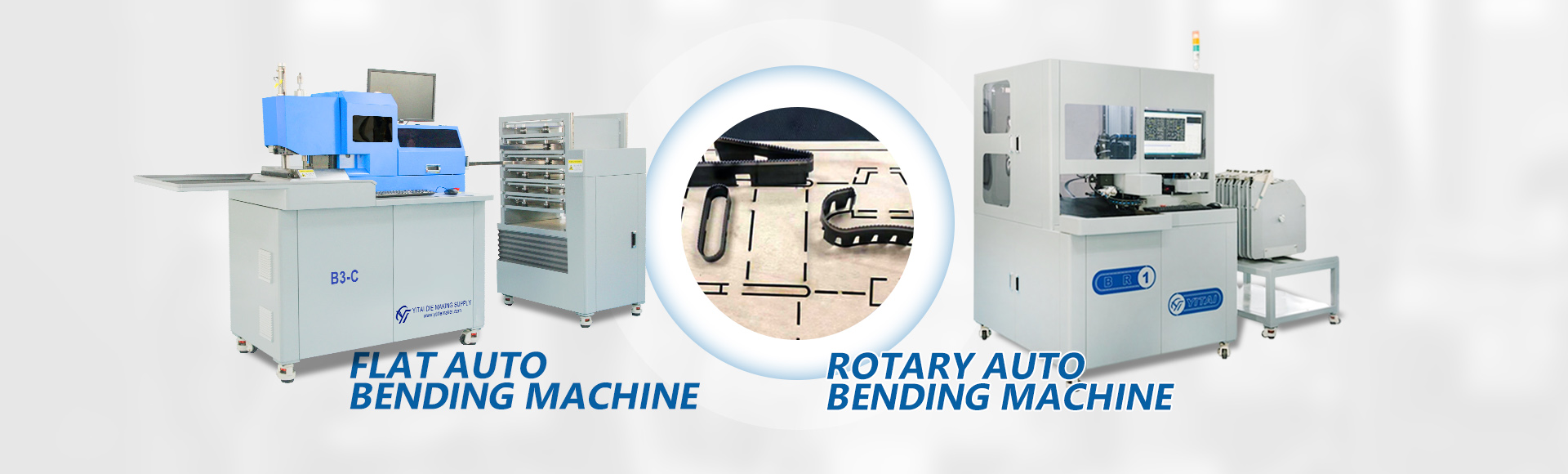

High-Precision Automated Steel Rule Processing for Professional Rotary Die Making

The YITAI Rotary Rule Bending Machine is an advanced bending system engineered specifically for rotary die manufacturing.

With its integrated multi-function structure, high-precision feeding system, and intelligent software control, the BR1 significantly enhances the efficiency, accuracy, and consistency of rotary steel rule processing.

Designed to support both rotary rules and flat steel rules, the BR1 enables die makers to complete bending, cutting, bridging, lipping, notching, and perforating—all in one machine.

What Makes the BR1 Essential for Rotary Die Making?

1. Full Support for Rotary & Flat Steel Rules

The BR1 is engineered for various rule types used across packaging and die-cutting industries:

- Rotary rules

- Flat cutting rules

- Creasing rules

- Laser-crease rules

Supported Rule Specifications

- Diameter (Rotary): 200–800 mm (automatic adjustment)

- Rule Height: 23.8–26.4 mm

- Rule Thickness: 0.71–1.42 mm

This wide compatibility covers nearly all rule standards used in professional rotary die making.

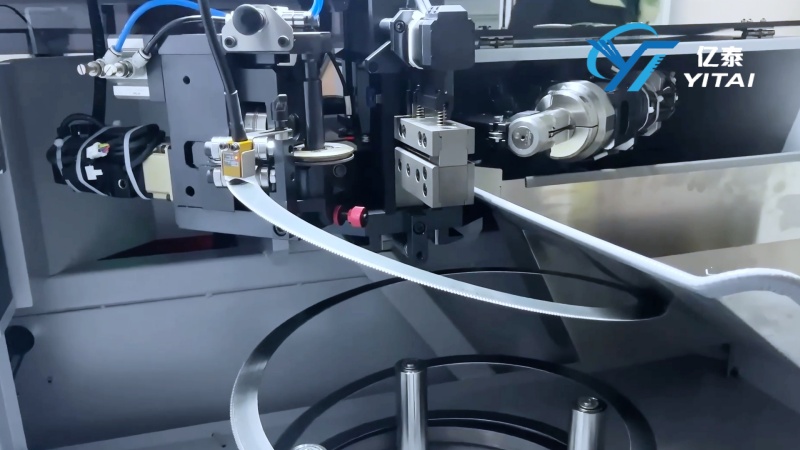

2. High-Precision Dual-Screw Feeding System

The patented dual-screw feeding mechanism provides:

- ±0.03 mm feeding precision

- Smooth and stable rule feeding

- No deformation regardless of rule hardness

- Improved bending consistency

A built-in jam-detection alarm automatically stops the machine to prevent tool damage.

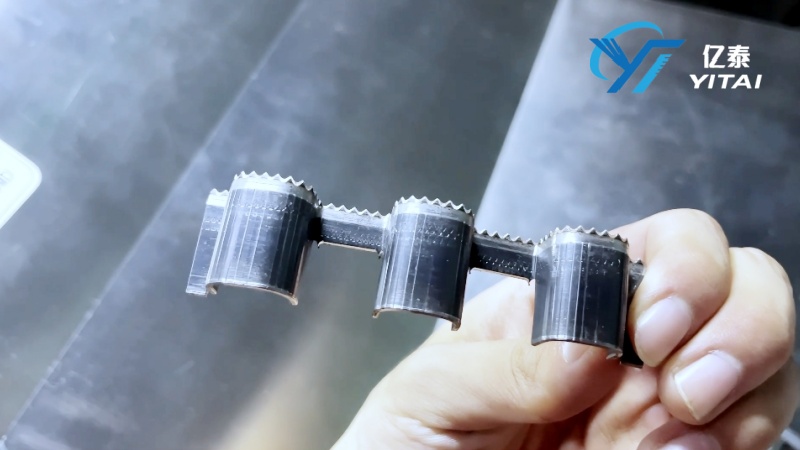

3. Integrated Multi-Function Processing System

The BR1 consolidates six major steel rule processes into one platform:

✓ Bending

High-precision bending with excellent flatness (±0.2 mm) and minimum bending radius R5 mm.

✓ Cutting

Automatic flat cutting ensures clean and accurate rule lengths.

✓ Bridging

Software-controlled bridge height: 8–18 mm, adjustable without changing molds.

✓ Lipping

Consistent lipping for secure and stable rule installation.

✓ Notching

- 90° notches

- Slot-shape notches

- Automatic notch at bending positions (for flat rules)

✓ Perforating

Perforation sizes can be customized based on user requirements.

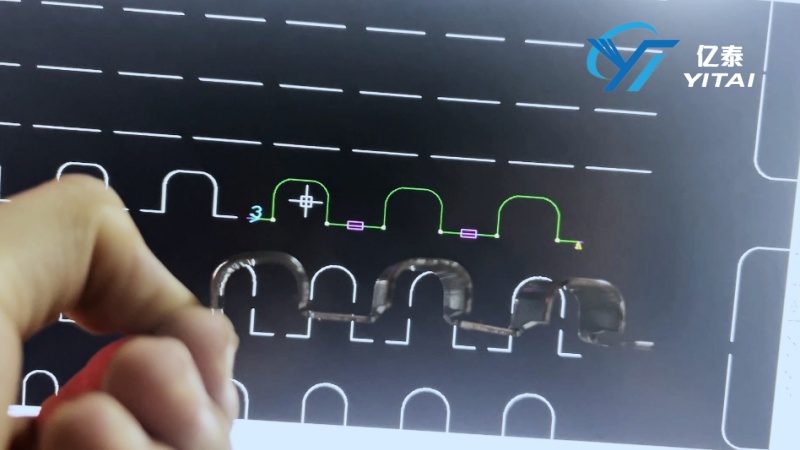

4. One-Click Software Automation

The BR1 uses YITAI’s advanced Windows 10–based rule processing system, offering:

- Multilingual interface

- DXF / DWG / CF2 file compatibility

- Auto-adjustment for bridge height and lipping

- Operator-friendly CAD interface

- Intelligent protection and monitoring

This drastically reduces setup time and makes the machine easy for new operators to learn.

5. 6-in-1 Automatic Rule Feeder

The intelligent auto-feed system includes:

- Six individual coil holders

- Smooth automatic switching

- Software-managed feeding

- Continuous operation without manual intervention

This greatly increases productivity and reduces labor workload.

6. Industrial-Grade Durability and Fast Maintenance

- High-speed steel (Japan imported) punching dies

- Quick mold replacement—within 3 minutes

- Reinforced machine frame for long-term stability

- Components designed for heavy-duty daily operation

The BR1 is engineered for high-volume rotary die production environments.

TECHNICAL PARAMETERS

| Model | BR1 |

|---|---|

| Rule Thickness | 0.71 / 1.07 / 1.42 mm |

| Rule Height | 20–27 mm |

| Blade Diameter | 250–700 mm |

| Bridge Height | 8–18 mm(Die Punching) |

| 180° Bend Min. Radius | R5 mm |

| Min. 90° Bend Length | 5 mm |

| Feeding Accuracy | ±0.03 mm |

| Bending Flatness | ±0.2 mm |

| Functions | Bending, Lipping,Cutting, Bridging, Notching, Perforation |

| Auto-Notching | 90° / Slot |

| Cutting | Auto Flat Cutting |

| File Format | DXF, CF2, DWG |

| Operating System | Windows 10 |

FEATURE OVERVIEW

1. Fully Automatic Operation

The BR1 completes:

- Feeding

- Bending

- Shearing

- Punching

- Bridge forming

…all in one automated workflow.

2. Smart Feeding System

- Automatically adapts to different rule heights

- Prevents deformation from soft/hard rule variations

- Jam alarm stops the machine and protects the tooling

3. Integrated Punching / Lipping / Cutting Mold Set

- Bridge, lipping, and flat cut within one mold set

- Software-controlled height adjustments

- One set of molds compatible with multiple rule specifications

- Japanese HSS punching die for long-lasting performance

4. High-Precision Bending System

- High-strength bending tools for long service life

- Quick tool adjustment for different materials

- Ensures excellent bending shape and repeatability

5. Advanced Software System

- Windows 10 platform

- Self-developed YITAI bending software

- Supports DXF, CF2, DWG file formats

- User-friendly interface for fast learning

- Multilingual support

6. Automatic Cutter System

- Six independent rule holders

- Intelligent safety protection to prevent accidental injuries

Why Choose the YITAI BR1 for Rotary Die Making?

✔ Faster Production

6-in-1 processing means fewer setups and higher throughput.

✔ Higher Precision

Software-controlled dimensioning and dual-screw feeding deliver die-making accuracy.

✔ Lower Labor Costs

A single operator can complete the full bending workflow.

✔ Universal Compatibility

Supports most rotary and flat rule standards used worldwide.

✔ Long-Term Reliability

Industrial-grade build designed for 24/7 die shop operation.

CONCLUSION

The YITAI BR1 Rotary Rule Bending Machine is a highly efficient, accurate, and versatile solution for professional rotary die-making.

Its combination of advanced feeding, shaping, bending, and intelligent software makes it ideal for:

- Rotary die manufacturers

- Corrugated box factories

- Printing & converting plants

- Die-making workshops seeking automated precision

BR1 strengthens production quality, shortens lead time, and reduces labor intensity — making it a valuable asset for any rotary die-making operation.