Manual Die Cutting vs Laser Die Cutting

12 Frequently Asked Questions Die-making Manufacturers Ask Before Upgrading

In die-making production, many factory owners search online with questions like:

- Is laser die cutting better than manual die cutting?

- Should I upgrade from a sawing machine to a laser die board machine?

- What is the real difference between manual and laser die cutting?

If you are considering equipment upgrades, this FAQ guide will help you understand the key differences from a practical production perspective.

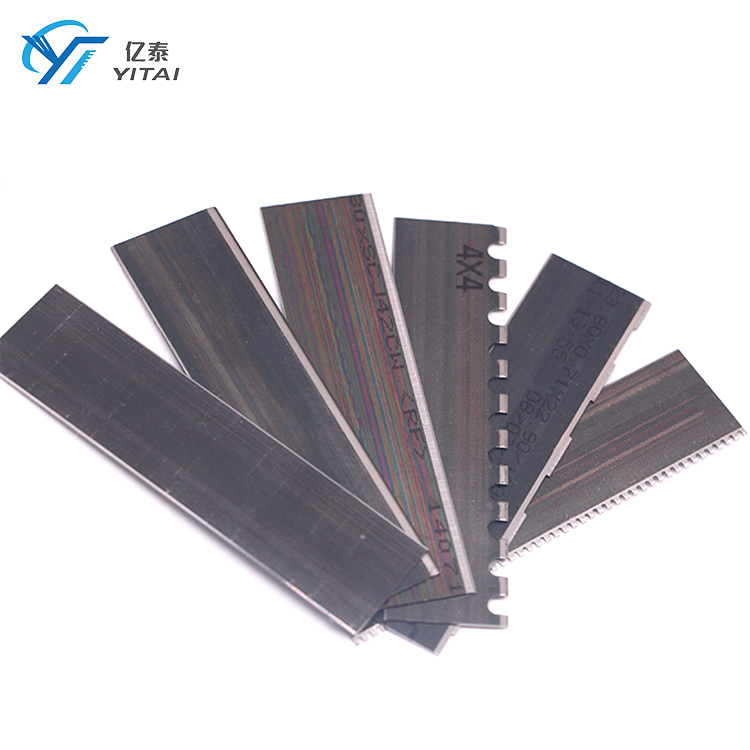

Essential Products for Manual Die-Cutting Factories

Q1: What is manual die cutting?

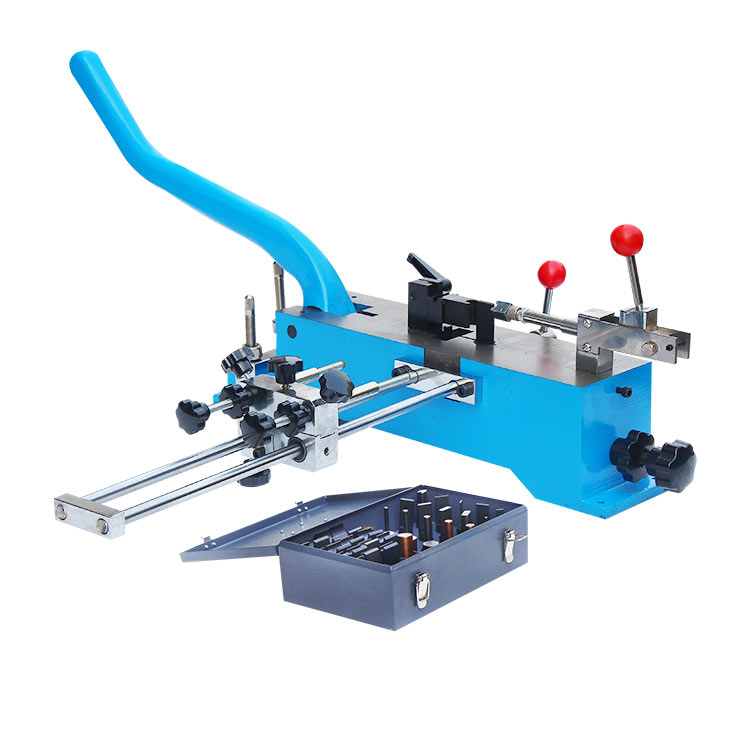

Manual die cutting (also called sawing machine die processing) uses:

- Foot-controlled electric saw blades

- Manual drilling

- Hand-drawn cutting lines

It is a traditional mechanical method for cutting die boards.

This process relies heavily on operator experience and manual precision.

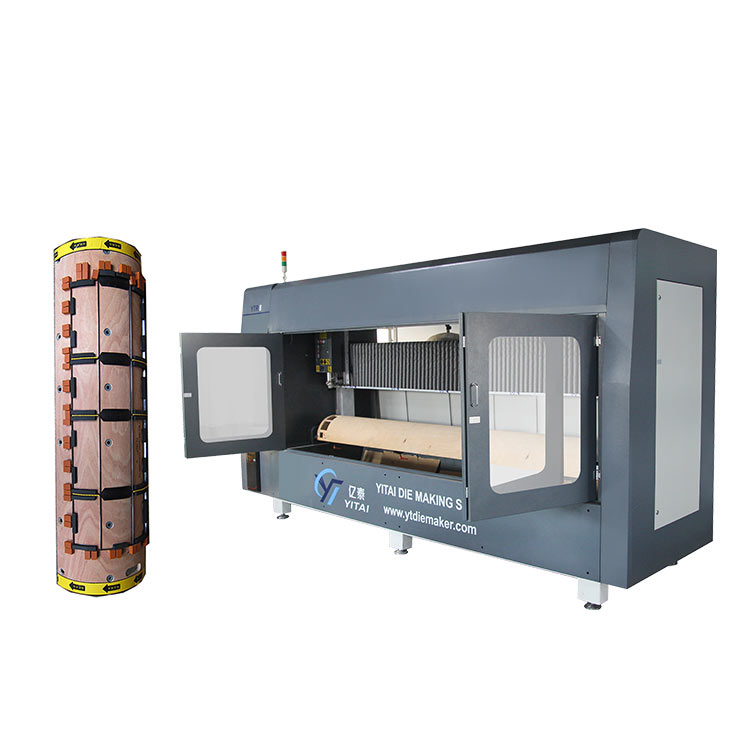

Manual Die-Cutting Equipment for Rotary Die Shop

Q2: What is laser die cutting?

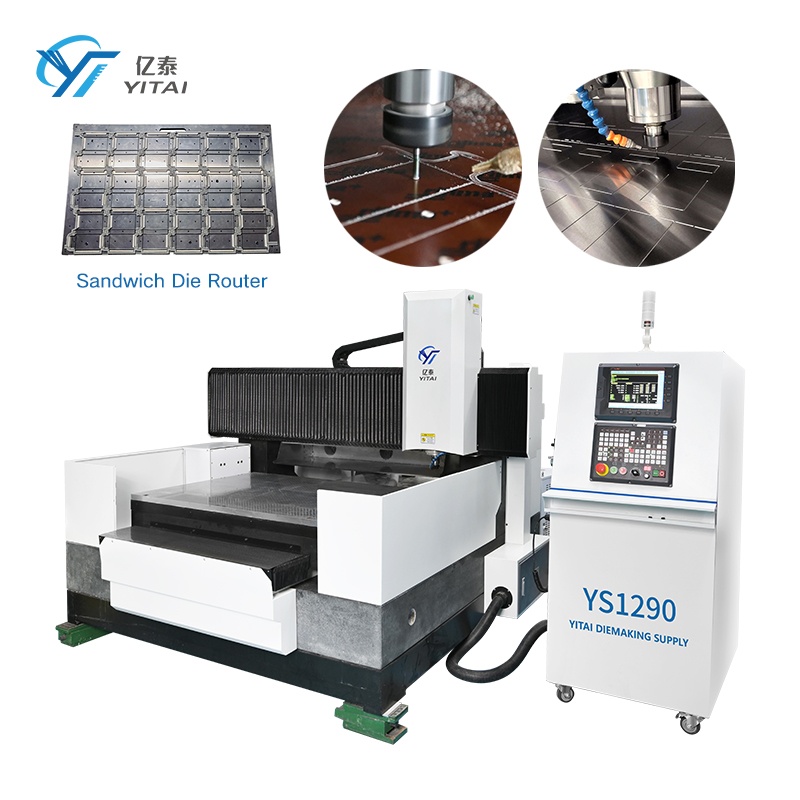

Laser die cutting uses:

- CNC-controlled laser beams

- Computer-designed cutting paths

- Automatic slot parameter settings

It is a non-contact, high-precision digital process that replaces manual sawing with laser ablation.

Die Board Laser Cutting Machine

Q3: Which method is more accurate?

Laser die cutting is significantly more precise.

- Manual processing often struggles with consistent tolerance control.

- Laser systems can maintain accuracy around ±0.05 mm under stable conditions.

For complex die boards or high-precision packaging, laser cutting provides much better repeatability.

Q4: Is laser die cutting faster than manual die cutting?

Yes — especially for medium and large orders.

Manual processing:

- Slower speed

- Dependent on operator skill

- Limited daily output

Laser cutting:

- Continuous operation

- Large-format processing

- 24-hour production capability

In many production environments, laser cutting can be more than twice as fast as manual sawing.

High-Speed Automatic Flat Die-Cutting Machines

Q5: Which method is better for complex graphics

Laser die cutting.

Manual machines struggle with:

- Tight curves

- Small details

- Intricate structures

Laser machines can cut any graphic that can be drawn digitally.

Q6: Is manual die cutting cheaper?

At first glance, yes — because:

- Equipment cost is lower

- Technology is simple

However, long-term costs may increase due to:

- High labor dependency

- Higher scrap rates

- Inconsistent quality

- Lower productivity

Laser machines require higher initial investment but often reduce overall operating cost in medium-to-large production environments.

Q7: Does manual die cutting cause more product scrap?

Often yes.

Because of:

- Blade deviation

- Uneven slot width

- Side slopes

- Dimensional errors

These issues can lead to poor die performance and higher material waste.

Laser cutting improves slot uniformity and reduces variation.

Q8: Which method is safer and cleaner?

Laser die cutting generally provides:

- Less dust

- Lower physical workload

- Cleaner production environment

Manual sawing generates significant dust and requires physical handling.

Q9: Can manual and laser die cutting coexist in one factory?

Yes.

Some factories use:

- Manual machines for simple, low-volume orders

- Laser machines for precision and complex production

However, as order complexity increases, laser processing typically becomes the primary solution.

Q10: When should I upgrade to laser die cutting?

Consider upgrading if:

- You receive complex die board orders

- Accuracy complaints are increasing

- Labor costs are rising

- Production efficiency needs improvement

- You want to expand into higher-end packaging markets

Laser technology supports scalable growth.

Q11: Is manual die cutting outdated?

Manual die cutting is not completely obsolete, but it is increasingly limited in modern production environments that require:

- Higher precision

- Faster turnaround

- Complex graphics

- Digital workflow integration

Laser die cutting aligns better with modern manufacturing standards.

Q12: Which solution is right for my factory?

Ask yourself:

- What is my average order complexity?

- How important is precision?

- Is labor cost increasing?

- Do I plan to expand production capacity?

If your production demands stability, precision, and scalability, laser die cutting offers clear long-term advantages.

Final Summary

| Factor | Manual Die Cutting | Laser Die Cutting |

|---|---|---|

| Precision | Limited | High |

| Efficiency | Low–Moderate | High |

| Labor Dependence | High | Low |

| Complex Designs | Limited | Excellent |

| Scalability | Limited | Strong |

| Initial Cost | Low | Higher |

There is no universally “best” solution — only the right technology for your production stage.

However, for manufacturers aiming for precision growth and stable long-term development, laser die cutting has become the industry trend.