How To Set-up A Rotary Die Shop

Introduction

Launching a rotary die shop requires precision equipment, skilled operators, and a streamlined workflow to meet the demands of high-speed corrugated packaging production.

YITAI’s One‑Stop Die Making Solution guides you from facility planning to full-scale rotary die production.

Step 1: Choose Rotary Die Production

-

Used for: High-speed rotary die-cutting lines

-

Substrate: Corrugated sheets, flexible materials

-

Common in: Large-volume corrugated factories

Tip: Start with flat dies for smaller production runs, then expand into rotary dies for higher volumes.

Step 2: Workshop Planning & Utilities

-

Floor space: ~300–500 m²

-

Electrical: Three-phase power (380 V), minimum 100 kW

-

Ventilation: Fume extraction systems for laser and cutting areas

-

Layout zones: Rotary laser area, CNC router, rule processing, assembly, QC, storage

YITAI provides tailored floor plans to match your equipment and space.

Step 3: Complete Equipment Configuration

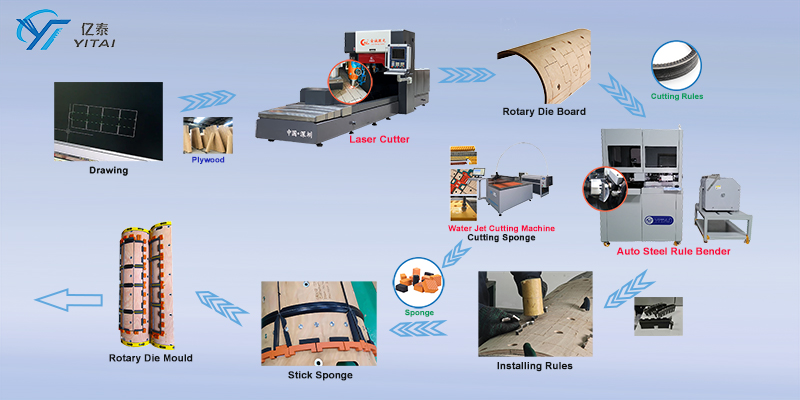

Rotary Die Production Process & Equipment

| Process | Equipment | Purpose |

|---|---|---|

| Rotary Board Cutting | Rotary Laser Cutter, CNC Rotary Router, Rotary Laser Plywood | Cuts curved die board precisely for rotary shells |

| Rotary Rule Processing | Rotary Rule Bending Machine, Rotary Cutting Rules | Shape and notch steel rules according to die design |

| Manual Adjustment & Assembly | Manual Bender, Grinding Tools, Jig Saw | Adjust complex or fine-shaped rules; ensure accurate installation |

| Shell Handling & Rule Mounting | Shell Handling & Rule Mounting Tools | Mount die board and rules onto rotary shell |

| Accessory Integration | Notchers, Rubber/Sponge Cutting Tools | Add ejection rubber and precision cuts |

All machines feature user-friendly software and come in starter or professional packages.

Step 4: Die-Making Consumables & Accessories

-

Steel rules: Cutting, creasing, perforating

-

Rotary rubber: Ejection material

-

Rotary die boards: High-grade plywood

-

Assembly tools: Rule holders, nails, adhesives

Starter kits available for immediate use.

Step 5: Operator Training & Startup Support

-

Machine delivery & installation

-

On-site or remote training

-

Multilingual manuals

-

Sample files & standard die templates

-

Ongoing after-sales support

Your team can be production-ready within days.

Step 6: Suggested Staffing Structure

| Role | Quantity | Notes |

|---|---|---|

| Laser technician | 1 | Rotary laser cutting |

| Rule bending technician | 1 | Operates rotary bender |

| Assembler | 1–2 | Install rules and rubbers |

| Supervisor | 1 | Oversees production & QC |

| Sales/support | Optional | Customer communication |

4–6 people can efficiently manage a rotary die shop.

Why Choose YITAI’s One‑Stop Rotary Die Solution?

-

40+ years of industry experience

-

Complete rotary die setup capabilities

-

Customized equipment packages

-

Training & installation support

-

Full material supply chain

-

Scalable solutions – from starter kits to full automation

-

Serving customers in 80+ countries