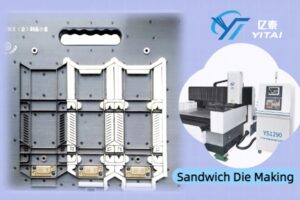

High-Precision Steel Rule for Clean & Burr-Free Die-Cutting

In precision die-cutting applications, cutting quality directly determines product appearance and production stability.

The Mirror Cutting Rule is specially developed for industries that require ultra-clean cut edges, minimal friction, and high dimensional accuracy.

Through advanced mirror polishing technology, the cutting edge achieves superior sharpness and smoothness, making it ideal for high-end and delicate material processing.

Specifications

| Parameter | Specification |

|---|---|

| Thickness | 0.71 mm (2PT) / 1.07 mm (3PT) / 1.42 mm (4PT) |

| Height | 23.6 mm / 23.8 mm |

| Edge Angle | 42° / 52° |

| Edge Hardness | HS76 / HS80 |

| Body Hardness | HS48 / HS50 / HS52 |

Key Features

Mirror-Polished Cutting Edge

The blade edge is processed with precision mirror grinding technology, resulting in:

- Sharper cutting performance

- Reduced friction during die-cutting

- Cleaner and smoother cut surface

- Minimal burrs and edge deformation

This significantly improves cut quality, especially for coated or laminated materials.

Lower Friction & Enhanced Surface Finish

Due to the ultra-smooth blade surface:

- Cutting resistance is reduced

- Heat generation is minimized

- Material surface remains neat and consistent

This is particularly beneficial when processing sensitive films and high-value materials.

Excellent Bending Performance

The steel body maintains balanced hardness and flexibility, allowing:

- Smooth bending without cracking

- Stable forming of complex die shapes

- Adaptability to intricate angles and tight radii

Suitable for high-precision die structures.

Recommended Applications

Electronics & Precision Industries

- Semiconductor materials

- Touch screens

- Polarizing films

- Mirror molds

Plastic & Film Materials

- PET films

- PP films

- PVC sheets

- Blister packaging

- Eyeglass lenses

Surface-Processed Paperboard

- Laminated cardboard

- Varnished paperboard

- Surface-coated packaging materials

Mirror cutting rule ensures clean edges even on high-gloss or surface-treated substrates.

Why Choose Mirror Cutting Rule?

Compared with standard steel rules, Yitai mirror cutting rules offer:

- Higher edge sharpness

- Improved cut surface quality

- Reduced material resistance

- Longer stable cutting performance in precision applications

It is especially recommended for high-value products where appearance and dimensional accuracy are critical.