Reliable Die Cutting and Lipping Knife Machine for Professional Die Makers

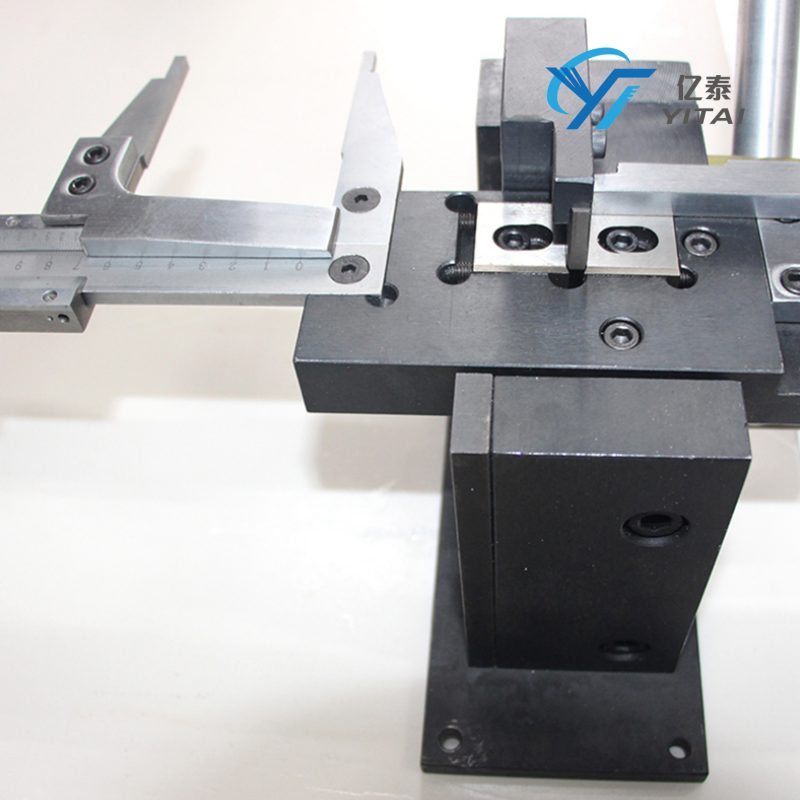

In steel rule die production, precision preparation of every rule directly affects die performance. The Manual Lipping Machine, also known as a Die Cutting and Lipping Knife Machine, is a specialized workshop tool designed to form accurate lips on steel rules used for cutting and creasing paper, cardboard, and corrugated board.

Developed for practical die shop use, this machine delivers consistent mechanical performance without relying on electricity, electronics, or magnetic systems — making it a dependable solution for both new and established die-making operations.

YTLC-40 Manual Lipping Machine

What Is Lipping in Die Making?

Lipping is a key preparation step in steel rule die manufacturing. It involves forming a small, controlled bend (lip) at the end of a steel rule. This structural feature helps:

- Secure the rule firmly inside the die board

- Improve positional stability during die cutting

- Reduce the risk of rule loosening over time

- Maintain consistent cutting and creasing accuracy

Proper lipping contributes directly to die durability and production reliability — especially in high-speed packaging lines.

Designed for Real Die Shop Conditions

This Manual Lipping Machine is engineered specifically for the needs of die makers working with:

- Folding carton dies

- Corrugated board dies

- Paperboard packaging dies

- Creasing and combination rules

Its manual design allows operators to carry out precise lipping with full tactile control, which many experienced die makers prefer when working with different rule profiles.

Key Features Backed by Practical Experience

Fully Manual, No Power Required

Unlike powered systems, this Die Cutting and Lipping Knife Machine operates entirely by mechanical force.

Advantages include:

- No electrical dependency

- No risk of electronic failure

- Suitable for workshops with limited infrastructure

- Lower long-term maintenance costs

This makes it especially useful for start-up die shops and facilities needing a reliable backup tool.

Consistent and Controlled Lipping

The machine structure is designed to guide the steel rule securely during operation, helping operators achieve:

- Uniform lip angles

- Stable insertion into die boards

- Reduced installation errors

Consistent lipping improves overall die assembly quality and extends die service life.

Durable Construction for Daily Production

Built from robust materials suitable for industrial environments, the Manual Lipping Machine withstands frequent use in busy die-making workshops while maintaining stable mechanical performance.

Essential Equipment for New Die Making Workshops

Industry practice shows that a newly established die-making shop typically begins with a set of core manual machines. The Manual Lipping Machine is one of the fundamental tools in this workflow.

Basic manual equipment for die making includes:

- Manual Bender Machine – for shaping steel rules

- Manual Cutting Machine – for cutting rules to required lengths

- Manual Lipping Machine – for forming secure lips on steel rule ends

- Manual Punching Machine– for creating precise bridge holes on pre-bent steel rules used in die cutting applications.

- Flat Die Board Plywood

- Flat Cutting Rules & Creasing Rules

- Die Making Machines

Together, these machines form a practical and cost-effective foundation for steel rule die production.

Why Die Makers Choose Manual Lipping Machines

✔ High reliability with simple mechanics

✔ No dependency on power supply

✔ Precise control preferred by experienced operators

✔ Low maintenance and long service life

✔ Ideal for small to medium die-making businesses

For workshops focused on consistent quality and practical operation, the Manual Lipping Machine remains a trusted and widely used solution in the die-cutting industry.