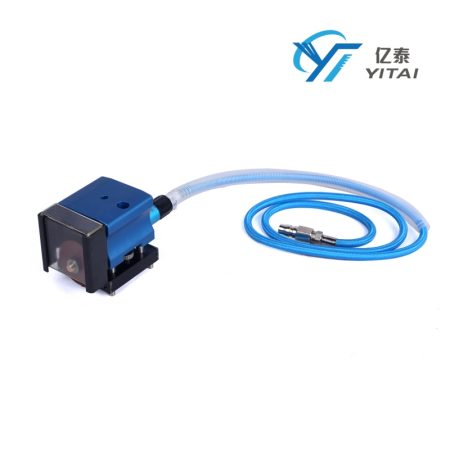

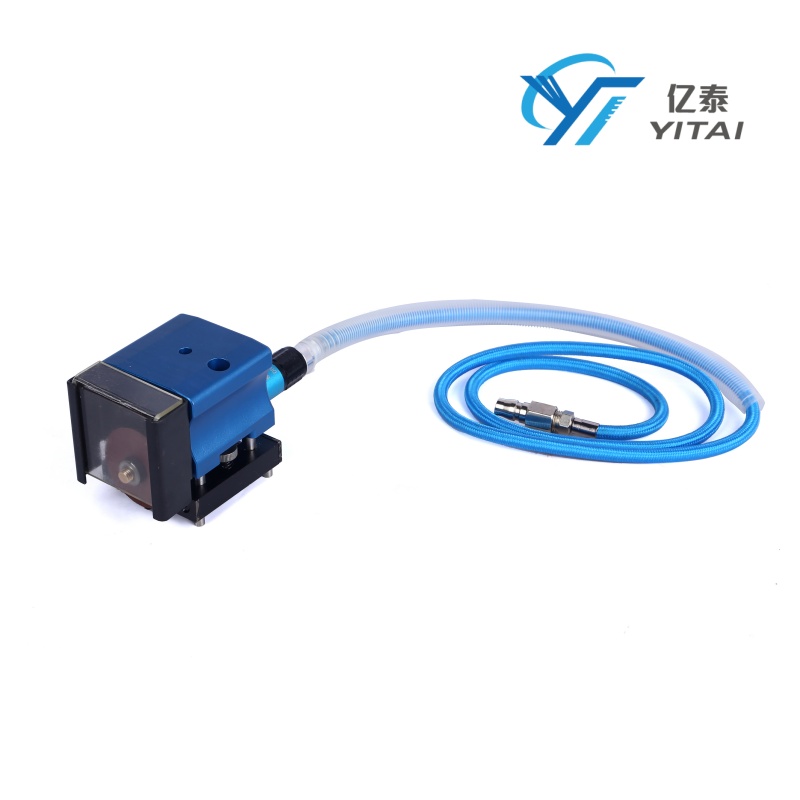

Hand-Operated Pneumatic Nick Grinder for Steel Rule Dies

In die making, precision is everything. A properly formed nick ensures clean separation of materials while maintaining sheet stability during stripping and blanking. This Nick Grinder for die making is a compact, hand-operated pneumatic tool designed to create accurate, consistent nicks on steel rule cutting dies.

Built for die shops and packaging manufacturers, it offers controlled grinding performance, operator-friendly handling, and reliable results across various die applications.

Yitai Nick Grinder

What Is a Nick Grinder?

A Nick Grinder for die making is a specialized tool used to grind small notches (nicks) into steel rule cutting blades. These nicks help:

- Prevent sheets from falling apart too early

- Control material separation during die cutting

- Improve stripping efficiency

- Reduce production waste

Proper nick depth and consistency are critical to die performance, which is why precision control is essential.

Nick Grinder for Die Making

Key Features

Adjustable Nick Depth Control

Different cutting jobs require different nick strengths. This machine allows operators to easily adjust nick depth using a control screw, ensuring:

- Accurate and repeatable results

- Better control over material holding force

- Compatibility with various die-cutting applications

Nick depth should always be determined according to die design. Excessive depth may cause abnormal grinding wheel wear and reduce tool life.

Pneumatic Hand Operation for Flexibility

This Nick Grinder for die making is pneumatically powered and hand-operated, making it ideal for:

- On-bench die processing

- Quick adjustments and repair work

- Workshops requiring mobility and ease of use

The lightweight structure helps reduce operator fatigue during extended use.

Variable Speed Motor Control

A switch located at the rear of the device allows operators to:

- Start or stop the motor easily

- Adjust grinding speed as needed

This ensures smoother grinding and better control when working on different blade thicknesses or materials.

Stable Positioning for Accurate Grinding

During operation, a locating device helps position the grinder precisely on top of the steel rule. This ensures:

- Consistent nick placement

- Reduced risk of slipping

- Cleaner, more uniform grinding marks

To create a nick, the operator positions the tool using the locator and presses the grinding wheel steadily and quickly against the cutting rule blade.

Applications

This Nick Grinder for die making is widely used in:

- Carton box die production

- Corrugated packaging dies

- Label and folding carton dies

- Die repair and modification work

It is an essential tool for die makers who need precise control over sheet holding strength and cutting performance.

Benefits for Die Workshops

✔ Improves die-cutting quality

✔ Enhances stripping performance

✔ Reduces material waste

✔ Extends die service life through proper nick control

✔ Easy to operate with minimal training

Designed for Practical Die Shop Use

The tool is engineered to meet the daily needs of die makers:

- Compact and easy to handle

- Stable pneumatic performance

- Simple mechanical adjustment

- Suitable for various steel rule sizes

Whether you are producing new dies or modifying existing ones, this Nick Grinder for die making provides the precision and reliability required in modern packaging and die-cutting production.