In high-end cigarette packaging, dimensional accuracy, cutting consistency, and long-term stability are non-negotiable requirements. Even minimal deviations can affect carton appearance, machine efficiency, and brand presentation.

For this reason, sandwich cutting dies—also known as laminated cutting dies—have become the industry standard for premium cigarette cartons, especially in high-speed, large-volume production environments.

Based on practical manufacturing experience, this article explains the structure, material selection, and key manufacturing steps of sandwich cutting dies used in cigarette packaging applications.

What Is a Sandwich Cutting Die?

A sandwich cutting die adopts a multi-layer laminated structure, typically consisting of:

- Top support board

- Middle functional layer containing cutting, creasing, and perforation rules

- Bottom reinforcement board

This layered construction forms a rigid “sandwich” system that significantly outperforms conventional single-layer wooden dies in terms of structural stability and dimensional control.

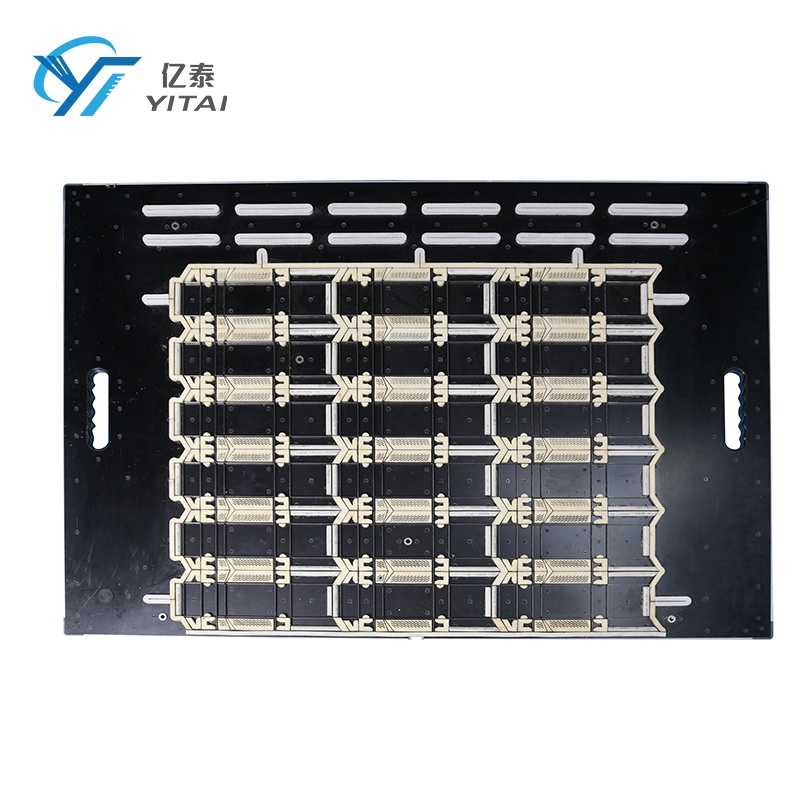

Cigarette Packaging Sandwich Cutting Die

Key Advantages for Cigarette Packaging

- Ultra-high cutting accuracy, typically controlled within ±0.05 mm

- Excellent dimensional stability under continuous high-pressure operation

- Long service life, suitable for millions of impressions

- Reliable performance on high-speed die-cutting machines

These characteristics make sandwich cutting dies particularly suitable for complex cigarette cartons, foil-laminated boards, and premium printing finishes.

Step 1: Structural Design and Engineering

The manufacturing process begins with precision engineering and die layout design, strictly based on the customer’s packaging and machine specifications.

Design Inputs Include:

- Carton dielines (AI / CAD files)

- Paperboard type and grammage

(white board, aluminum-foil laminated paper, composite structures) - Die-cutting machine models

(e.g. BOBST, Masterwork, SBL)

Engineering Focus Areas:

- Cutting rule paths and intersections

- Creasing rule positioning and height matching

- Perforation and tear-open structures

- Compensation for material thickness, folding behavior, and rebound

In cigarette packaging, tolerance control is extremely strict, with critical dimensions often required to stay within ±0.05 mm throughout the entire die.

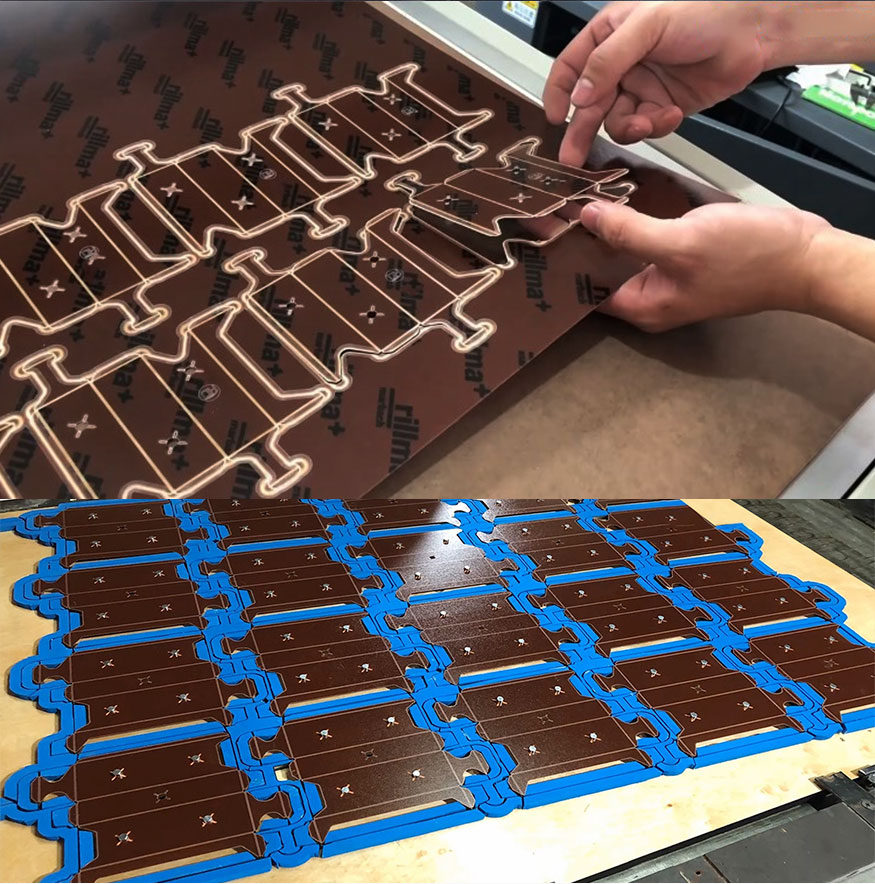

Step 2: Material Selection

Material selection directly determines the stability, lifespan, and cutting consistency of a sandwich cutting die.

1. Board Materials

A typical sandwich die consists of three functional layers:

- Top layer

Imported birch plywood or high-performance resin board, providing surface stability and flatness. - Middle layer

High-density plywood precisely machined to hold cutting, creasing, and perforation rules with minimal deviation. - Bottom layer

Hardwood plywood or aluminum plate, designed to resist long-term pressure, impact forces, and deformation.

This combination ensures that the die maintains its geometry even during extended high-speed production runs.

2. Cutting and Creasing Rules

- Cutting rules

High-carbon steel rules, commonly 23.8 mm height, selected for sharpness retention and wear resistance. - Creasing rules

Flat or rounded profiles, customized according to paper thickness and folding requirements. - Perforation rules

Precisely engineered for tear strips, opening features, and consumer-friendly pack access.

Each rule type is selected and configured to match the specific carton structure and material behavior.

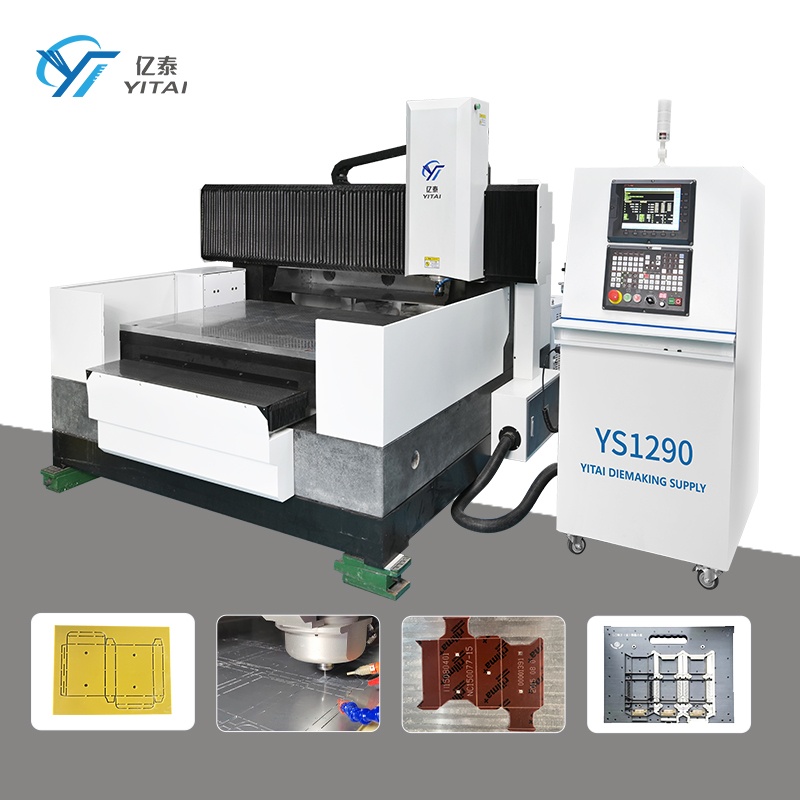

Step 3: CNC Slotting and Precision Machining

Once materials are prepared, CNC routers or laser machines are used to machine rule slots strictly according to the CAD design.

Critical Machining Parameters:

- Slot depth and width accuracy

- Verticality of the slots

- Positioning precision across the entire die

- Consistency between different areas of the layout

High vertical precision is essential. Even minor deviations can lead to:

- Incomplete cutting

- Edge bursting or cracking

- Creasing misalignment

- Instability during high-speed operation

For cigarette packaging, slotting accuracy directly determines final carton quality and machine efficiency.

Conclusion: Why Sandwich Cutting Dies Are Essential for Cigarette Packaging

Cigarette packaging places some of the highest technical demands on cutting dies in the packaging industry. The sandwich cutting die’s laminated structure, combined with precise engineering and controlled manufacturing, provides the accuracy and durability required for premium cartons and continuous high-speed production.

By focusing on design precision, material integrity, and machining accuracy, sandwich cutting dies deliver consistent results that meet both brand standards and industrial production demands.