LCB vs CB Steel Rule Die Cutting Blades

In steel rule die cutting, selecting the right die cutting steel rule is critical to achieve clean edges, stable cutting, and long tool life. Among all die cutting blades, LCB (Long Center Bevel) and CB (Center Bevel) are the two most commonly used profiles, each designed for different materials and cutting requirements.

1. LCB Die Steel Rule (Long Center Bevel)

Suitable Materials

- Thin paper

- Carton board

- Film

- Light corrugated board

Cutting Performance

- Produces extremely clean, sharp edges with minimal burrs

- Requires lower cutting pressure, reducing the risk of paper crushing or indentation

- Ideal for high-precision steel rule die cutting applications

Limitations

- When used on thick board or hard materials, the die cutting blade may not fully penetrate

- Cutting edge is more prone to chipping under high impact loads

Typical Applications

- High-end packaging

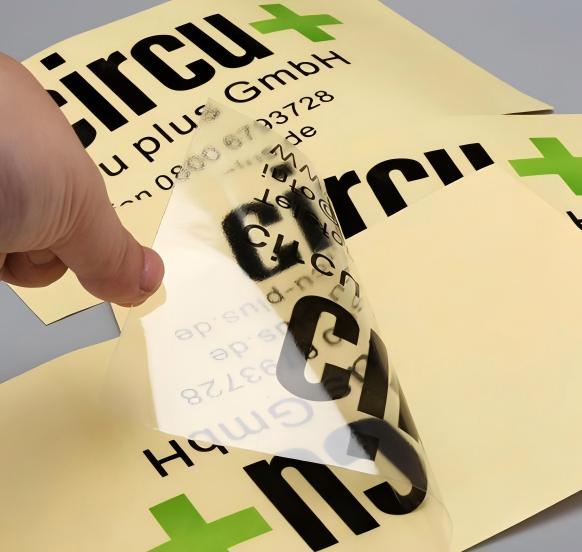

- Labels and stickers

- Fine printing and folding cartons

LCB Die Steel Rule for Thin Paper

2. CB Die Cutting Steel Rule (Center Bevel)

Suitable Materials

- Thick board

- Corrugated board

- Certain plastic sheets

Cutting Performance

- Stronger and more stable bevel structure

- Withstands higher impact forces during steel rule die cutting

- Excellent durability, less likely to roll or chip

- Performs reliably on hard or multi-layer materials

Limitations

- On thin paper, the cut edge may appear slightly rougher

- May leave minor burrs or indentations compared with LCB rules

Typical Applications

- Heavy-duty corrugated packaging

- Industrial cartons

- Plastic die cutting

die cutting blade used in hard materials

Summary Comparison

| Material Type | Recommended Steel Rule Die Blade | Cutting Result |

|---|---|---|

| Thin paper / film | LCB die steel rule | Sharp, smooth, high-precision |

| Carton board | LCB steel rule die cutting | Clean edges, minimal pressure |

| Thick board | CB die cutting steel rule | Stable, durable, strong impact resistance |

| Corrugated board | CB steel rule die blades | Reliable and long-lasting |

Expert Recommendation from a Steel Rule Die Maker

- Choose LCB die steel rule when edge quality and precision are the priority.

- Choose CB die cutting steel rule when material strength and durability matter more than surface fineness.

- For combined cutting and creasing operations, match the cutting rule with the appropriate steel creasing rule to ensure consistent results.

As an experienced steel rule die maker, selecting the right steel rule die blades ensures higher efficiency, better product quality, and longer die life across different materials.