When manufacturing rotary dies, the quality of the rotary die board (rotary shell) plays a critical role in cutting accuracy, machine stability, and tool lifespan. Poor-quality shells can lead to uneven cutting, vibration, and increased wear on laser or die-cutting equipment.

Check the Quality of Rotary Die Boards

Below is a simple 5-step inspection guide to help you quickly and accurately distinguish high-quality rotary die boards from inferior ones.

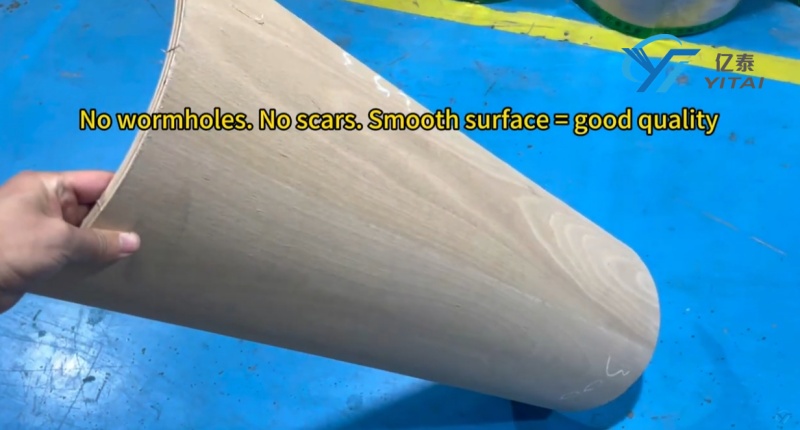

Step 1: Inspect the Surface

Carefully check the outer surface of the rotary shell for wormholes, scars, cracks, or defects.

- ✅ Smooth surface with no visible defects → High-quality board

- ❌ Rough surface with holes or cracks → Reject immediately

A clean and uniform surface indicates good raw material selection and proper processing.

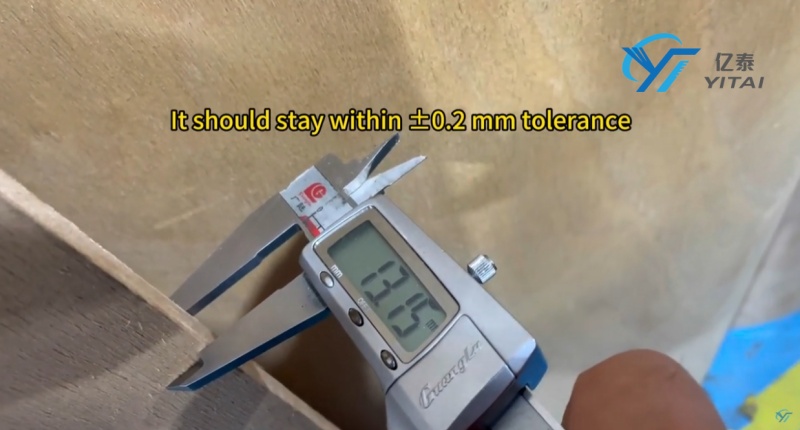

Step 2: Measure the Thickness

Use a caliper to measure the shell thickness at multiple points.

- Standard thickness tolerance: within ±0.2 mm

- Uniform thickness ensures better balance, stable rotation, and higher laser-cutting precision

Inconsistent thickness often leads to cutting deviation during production.

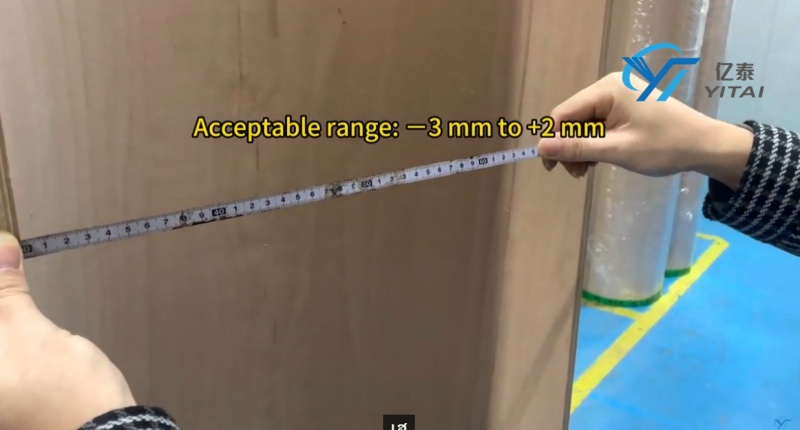

Step 3: Check Bottom & Middle Diameters

Measure the diameters at both ends and the middle of the rotary shell.

- Acceptable deviation range: −3 mm to +2 mm

This tolerance ensures the shell fits properly onto the rotary die-cutting drum, preventing installation issues and vibration during operation.

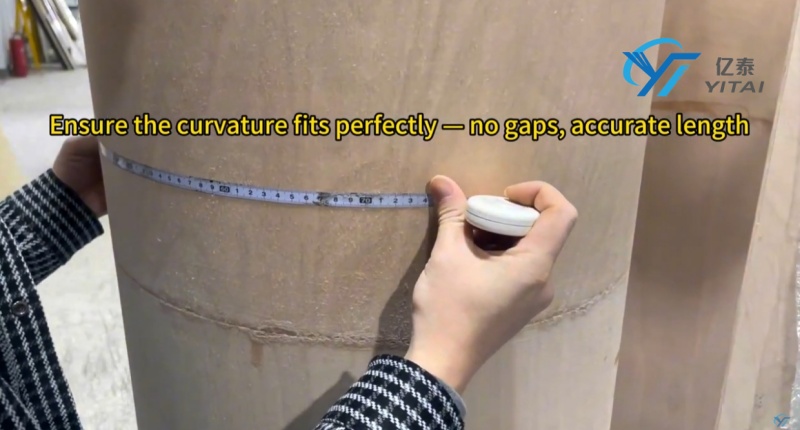

Step 4: Test Curvature & Length

Place the rotary shell on a standard curvature jig to check alignment.

- No visible gaps between the shell and jig

- Accurate overall length

A perfectly curved shell guarantees smooth rotation and consistent cutting performance on high-speed die-cutting machines.

Step 5: Conduct a Laser Cutting Test

Perform a rotary laser cutting test to evaluate cutting performance.

- Smooth, clean cutting edges after laser processing indicate:

- High-density wood structure

- Stable internal bonding

- Suitability for long-term die-making use

Poor edge quality usually means weak material density or internal defects.

YITAI Quality Assurance

At YITAI, every rotary die board undergoes strict dimensional inspection and laser cutting test verification before delivery.

Our rotary shells are engineered for high precision, strength, and long-term stability, supporting rotary die-cutting applications across:

- Packaging

- Printing

- Corrugated box production

We help die makers achieve consistent accuracy, reduced downtime, and extended die life.

▶ Watch the full inspection video here:

YouTube: How to Check Rotary Die Board Quality