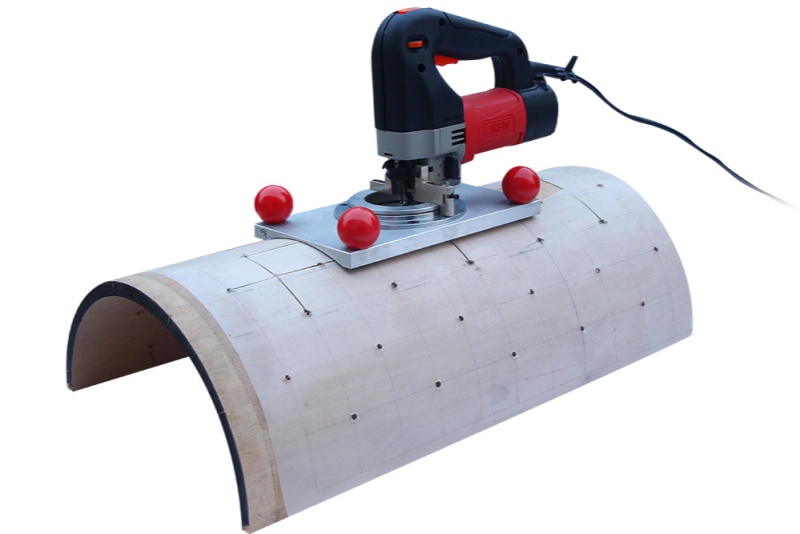

A Rotary Jigsaw Machine is a specialized power tool designed for precision cutting of curved, intricate, and irregular shapes in various materials. It operates using a reciprocating blade that moves rapidly in an up-and-down or orbital motion, allowing it to make detailed cuts with high accuracy.

Common Applications

- Custom Fabrication: Cutting intricate designs for crafts, signage, and inlays.

- Die Board Cutting: Creating precise shapes for cutting dies in packaging and printing industries.

- Template & Pattern Making: Used in woodworking, prototyping, and model making.

Key Features

- Versatile Cutting

- Ideal for cutting wood, plywood, MDF, acrylic, and other sheet materials commonly used in die-making, signage, and craftwork.

- Adjustable Speed

- Variable speed settings (e.g., 500–3000 strokes per minute) enable control for different materials and cutting complexities.

- Compact & Lightweight

- Easy to handle for extended use, reducing operator fatigue during detailed tasks.

- Precision & Control

- Enables tight-radius curves, sharp corners, and clean cuts for templates, molds, and custom designs.

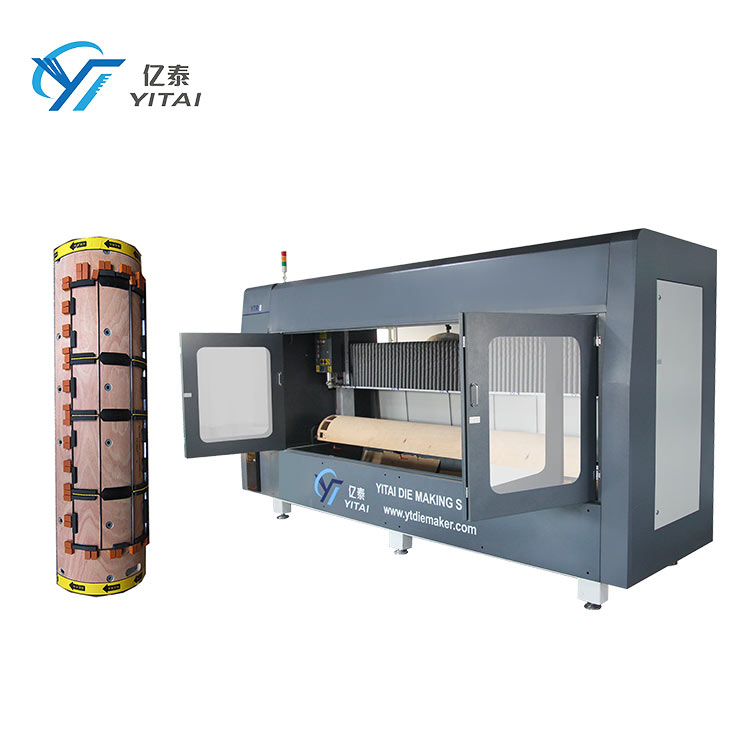

Rotary Die Cutting Machine Hand Operation

Machine Specifications

| Parameter | Model RJ-360 | Model RJ-487 |

|---|---|---|

| Max Cutting Depth | 60mm | 60mm |

| Power Supply | 220V, 50Hz | 220V, 50Hz |

| Rated Input Power | 550W | 550W |

| Load Current | 2.6A | 2.6A |

| No-Load Stroke Speed | 500–3000/min | 500–3000/min |

| Weight | 2.3kg | 2.3kg |

Key Advantages for Die-Making

- High Precision & Durability – Engineered to maintain cutting accuracy over extended use, reducing material waste and ensuring consistent die quality.

- Ease of Operation – Designed for intuitive use, enabling smooth cutting of complex shapes and contours commonly required in die board fabrication.

- Safe & Eco-Friendly Operation – Low noise, minimal vibration, and efficient dust extraction compatibility contribute to a safer and cleaner workshop environment.

Detailed Operating Instructions

1. Preparation

- Ensure the work area is clean and well-lit.

- Securely clamp the die board to prevent movement during cutting.

- Select the appropriate blade for the material (e.g., plywood, MDF, or acrylic).

- Connect the machine to a 220V, 50Hz power source.

2. Starting the Machine

- Place the saw at the edge of the die board, aligning the blade with the marked cutting line.

- Press and hold the red start button to activate the machine.

- Allow the blade to reach the desired speed (adjustable via speed control, if available) before beginning the cut.

3. Cutting Process

- Guide the saw steadily along the design lines, applying gentle forward pressure.

- For sharp corners or intricate patterns, reduce speed and use short, controlled movements.

- Let the blade do the work—avoid forcing the saw, which may cause blade deflection or breakage.

4. Completion

- Release the start button to stop the machine.

- Wait for the blade to come to a complete stop before setting the saw down.

- Unplug the machine after use.

Important Safety & Maintenance Notes

✅ Do’s:

- Always wear safety glasses and hearing protection.

- Use sharp, undamaged blades suitable for the material.

- Keep the saw base flat against the workpiece for stable cutting.

- Regularly clean the blade guard and ventilation slots to prevent dust buildup.

- Store the machine in a dry, dust-free environment.

❌ Don’ts:

- Do not operate in wet or damp conditions.

- Do not force the blade or cut at excessive speeds.

- Do not remove chips or debris while the blade is moving.

- Do not use damaged cords or plugs.

- Avoid cutting materials beyond the specified 60mm depth.

Maintenance Tips:

- Lubricate moving parts as recommended in the manual.

- Periodically check blade alignment and fastening.

- Inspect power cord and switch regularly for wear.

- Have electrical components serviced only by qualified personnel.

This machine is designed for precision die board cutting, offering reliability and control for professional die-making applications. For further technical support or blade recommendations, please consult our supplier team.