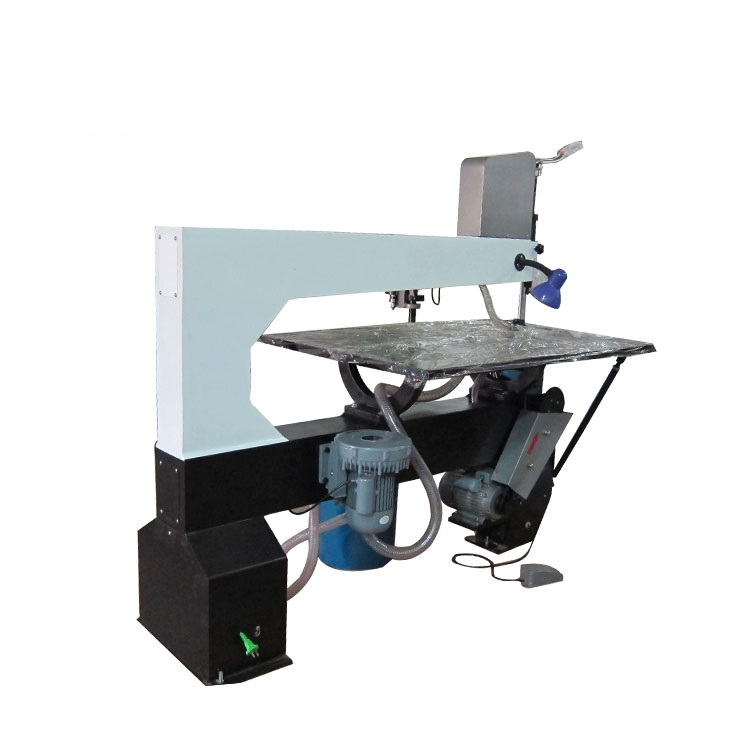

The YTJ series flat bed jig saw machine is specifically designed for die making, featuring an electric chucking saw blade, an automatic dust extraction system, an integrated sawdust collection device, and an air flotation die-cutting table. These advanced features enhance machine performance and operational convenience, making it an ideal choice for die makers seeking high efficiency and precision

Machine Parameters

| Model | YTJ-800B | YTJ-1000B | YTJ-1250B | YTJ-1250C | YTJ-1500C |

|---|---|---|---|---|---|

| Max Radius of Gyration (mm) | 800 | 1000 | 1250 | 1250 | 1500 |

| Max Die Cutting Thickness (mm) | 30 | 30 | 30 | 30 | 30 |

| Total Power (kW) | 0.9 | 0.9 | 0.9 | 1.1 | 1.1 |

| Saw Chucking Stroke (mm) | 25 | 25 | 25 | 25 | 25 |

| Working Table Size (mm) | 1300 × 650 × 1400 | 1520 × 700 × 1400 | 1770 × 800 × 1400 | 1770 × 800 × 1400 | 2070 × 1000 × 1400 |

Key Features

- Electric chucking saw blade for quick and stable blade changes

- Dual high-performance air pumps for efficient dust extraction

- Air flotation die-cutting table with a maximum radius of gyration of 1200mm to reduce friction and protect materials

- High-precision cutting quality to ensure accurate die dimensions

- Wide range of compatible jig saw blades available to suit different materials and cutting needs

Manual Jig Saw Die Board Cutter

Maintenance Tips

- Regularly check and tighten all screws to maintain machine stability and precision

- Clean the dust collection reservoir periodically to prevent dust buildup affecting the air flotation system

- Apply lubricant regularly to keep mechanical parts running smoothly

- Lubricate the square guide of the upper clip with grease every two weeks

- Ensure the lubrication oil level in the gearbox of the lower clip stays above the oil window line

Applications

- Suitable for precise flat cutting of die board materials including wood, plastic, and nylon

- Widely used in packaging die making and precision mold manufacturing industries

The YTJ Series flat bed jig saw machine combines advanced technology with user-friendly design to help die makers improve production efficiency and product quality. It is a reliable and essential tool for achieving stable and precise die cutting.