How to Choose the Right Ejection Rubber for Steel Rule Dies

— Ejection Sponge Rubber, EVA Ejection Rubber & Ejection Foam Explained

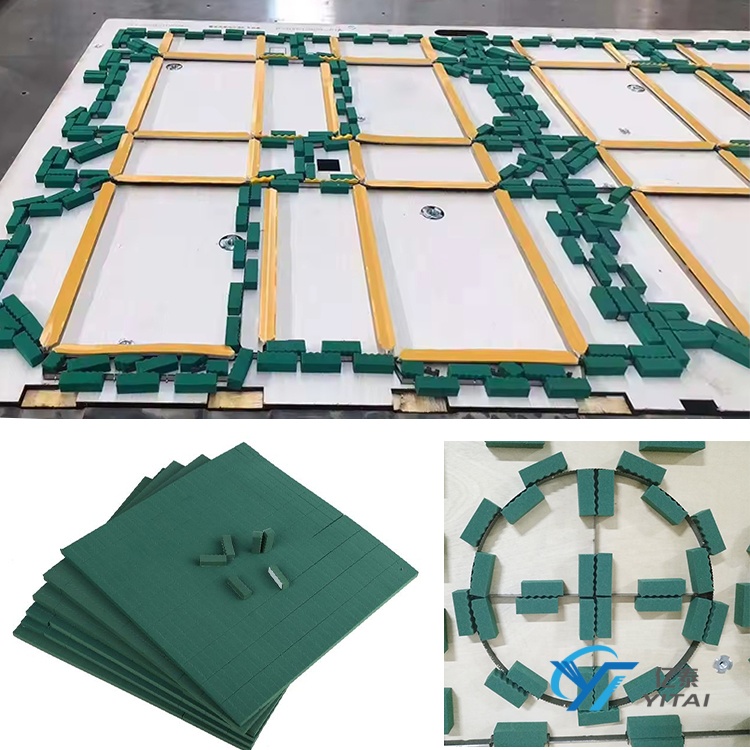

Selecting the correct ejection rubber—including ejection sponge rubber, steel rule die ejection rubber, EVA ejection rubber, or ejection foam for dies—is one of the most important factors in achieving clean die-cuts, stable rule life, and consistent production output.

Whether the rubber is placed on the flat die board or used as the counter pad/anvil, its hardness and rebound characteristics have a direct impact on cutting accuracy and overall die durability.

At YITAI Die Making Supply, with 40+ years of Taiwanese die-making expertise and 33 specialized factories worldwide, we help die makers optimize ejection performance through the right rubber selection.

Why Ejection Rubber Hardness Matters

Using the correct ejection sponge rubber / EVA ejection rubber improves the performance of any steel rule die:

Clean Cutting Quality

Prevents tearing, crushing, or incomplete cuts.

Protects Steel Rule Blades

Correct hardness reduces blade shock and premature dulling on steel rule die ejection rubber setups.

Smooth Material Ejection

High-rebound rubber pushes the sheet cleanly off the rule, essential for high-speed presses.

Factory Efficiency

Minimizes downtime caused by inconsistent cutting, poor ejection, or frequent rubber replacement.

Recommended Hardness for Ejection Rubber (Shore A)

| Application | Shore A Hardness | Why It Works |

|---|---|---|

| Pressure-sensitive labels / kiss-cut | 80–95 | Hard rubber prevents liner damage |

| Paperboard & folding cartons | 70–85 | Balanced hardness for clean cuts + ejection |

| Thin PET/PVC films | 75–85 | Prevents wrinkles & distortion |

| Foam / sponge materials | 50–70 | Softer rubber absorbs compression |

| Textile / leather | 60–75 | Avoids marking on flexible substrates |

| Metal foils | 85–95 | High hardness resists blade shock |

Rule of thumb:

- Softer rubber = easier ejection

- Harder rubber = more precision

Both EVA ejection rubber and ejection foam for dies are commonly used for softer applications requiring high rebound.

Matching Rubber to Material Thickness

| Material Thickness | Shore A | Rubber Height |

|---|---|---|

| ≤0.2 mm films | 80–90 | 2–3 mm |

| 0.2–0.6 mm paper | 75–85 | 3–4 mm |

| 0.6–1.5 mm cartons | 70–80 | 4–6 mm |

| 1.5–3.0 mm boards | 60–75 | 6–8 mm |

| >3.0 mm foam | 50–70 | 8 mm+ |

Blade penetration should exceed material thickness by 0.5–1.5 mm.

Counter Pads / Anvils (Shore D Scale)

Counter pads are harder than ejection rubbers:

- Kiss-cutting: Steel counter plates

- Through-cutting: UHMW-PE / nylon / polyurethane

- Harder pad = stable depth control

The anvil must always be harder than the ejection sponge rubber or EVA rubber on the die board.

Practical Best Practices for Die Makers

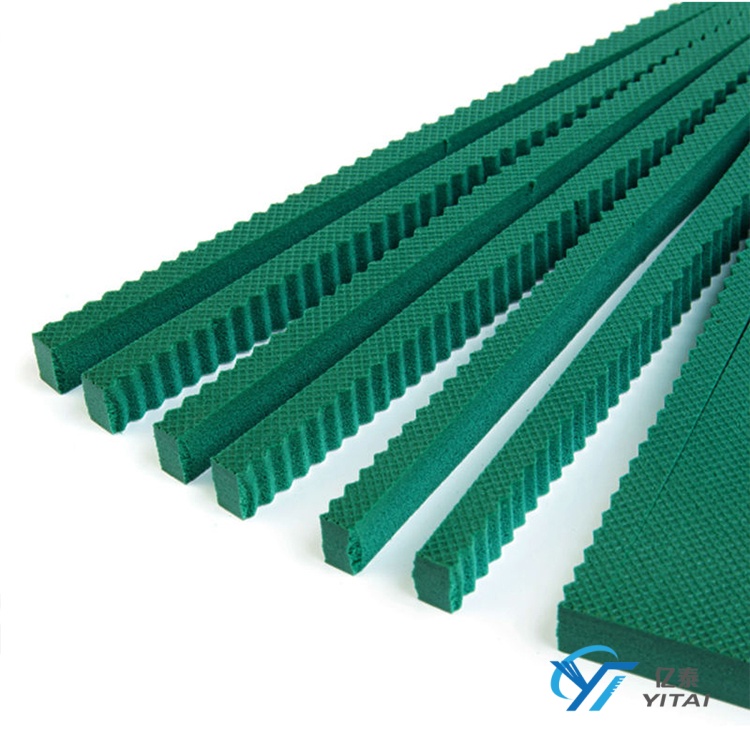

Setback

- 0.5–1.0 mm from rule for through-cut

- 1–2 mm for kiss-cut

Height Tolerance

Maintain ±0.1–0.2 mm for consistent depth.

Rubber Profiles

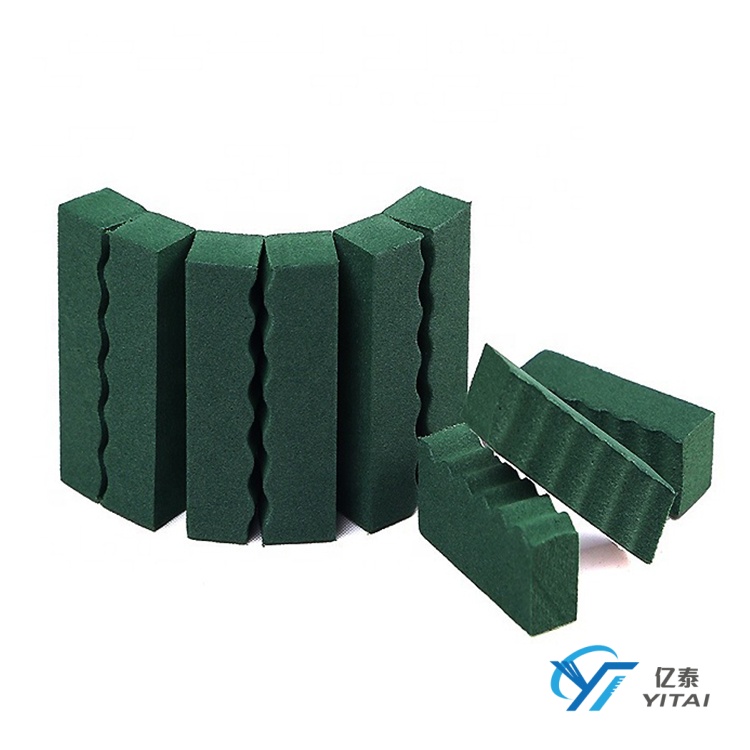

Beveled or scalloped profiles improve performance on curved lines.

Vent Gaps

Small gaps help eject tiny cut pieces and prevent sticking.

Troubleshooting Guide

| Issue | Likely Cause | Solution |

|---|---|---|

| Incomplete cut | Rubber too hard / too tall | Switch to softer sponge or EVA ejection rubber |

| Blade dulling fast | Hard rubber absorbing impact | Reduce hardness, consider coated rule |

| Poor ejection | Rubber too stiff | Use high-rebound ejection foam for dies |

| Crush marks | Rubber height too high | Lower height or use beveled profiles |

| Liner damage (kiss-cut) | Rubber too soft | Increase hardness / increase setback |

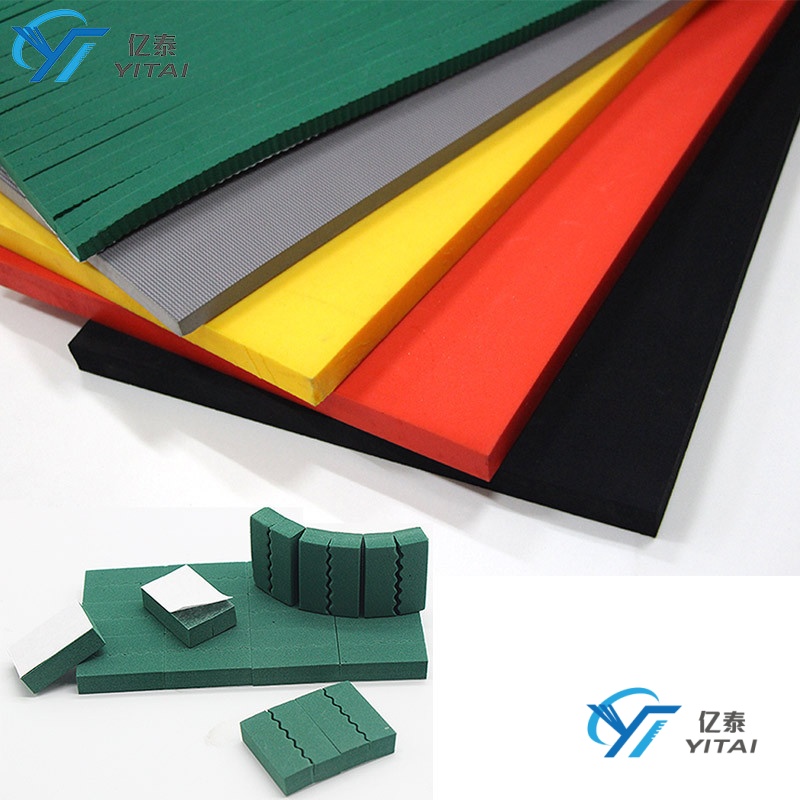

Materials at a Glance

Ejection Sponge Rubber (50–90 A)

- Excellent elasticity

- Ideal for general carton die making

- Cost-effective & easy to install

Steel Rule Die Ejection Rubber

- Engineered for long-run die cutting

- High rebound for corrugated packaging

EVA Ejection Rubber

- Smooth rebound, stable hardness

- Great for label, film, and kiss-cut jobs

Ejection Foam for Dies

- Softest option

- Best for uneven surfaces and cushioning needs

Composite Pads

- Hard base + soft top

- Precision + ejection performance combined

Partnering for Specialized Die-Cutting Applications

For advanced applications like:

- Multi-layer substrates

- Adhesive materials

- Thick foam or rubber

- Heat-resistant die-cutting

We provide custom solutions including:

- Multi-layer ejection pads

- Heat- and oil-resistant compounds

- Color-coded hardness rubber

- OEM die-cut shapes for die makers