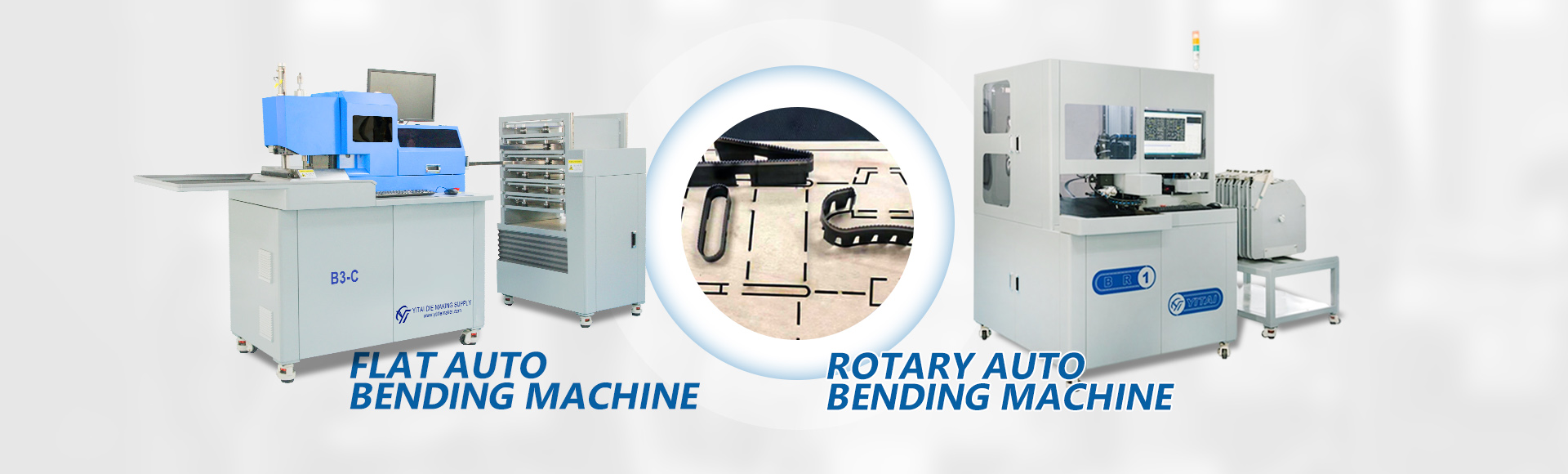

High-Precision Auto Bending Machine for Die Cutting | 2pt / 3pt / 4pt Steel Rule Processing

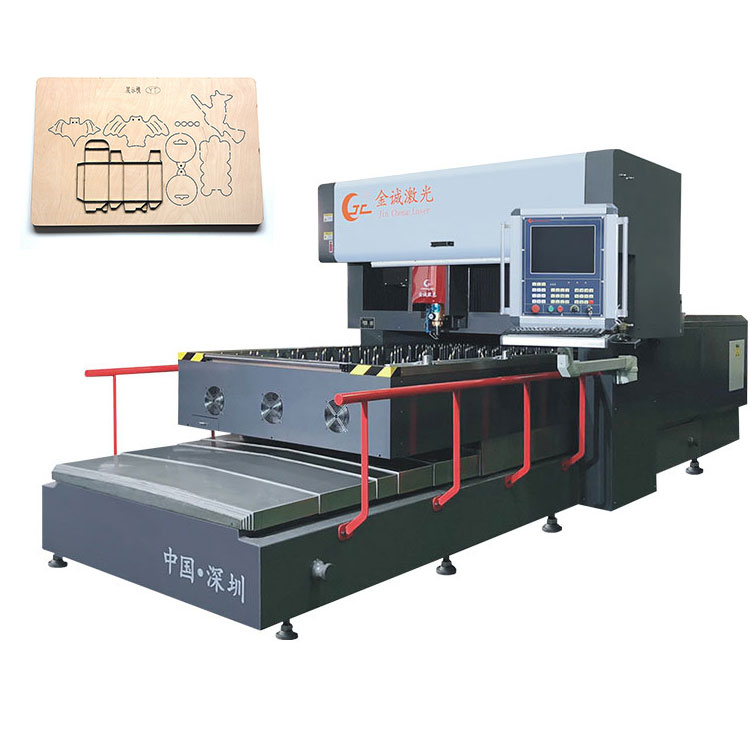

As the die-making industry moves toward higher precision and automation, professional diemakers increasingly rely on advanced auto bending machines for die cutting to improve efficiency and ensure accurate steel rule forming.

The B3 Series—manufactured by a leading auto bender machine factory in China—offers a fast, stable, and precise solution for cutting, bending, perforating, and notching 2pt, 3pt, and 4pt steel rules.

Designed for flat die board production, this auto bender machine China model delivers excellent performance with low energy consumption, high accuracy, and simplified operation.

B3 Auto Bending Machine — Steel Rule Capacity

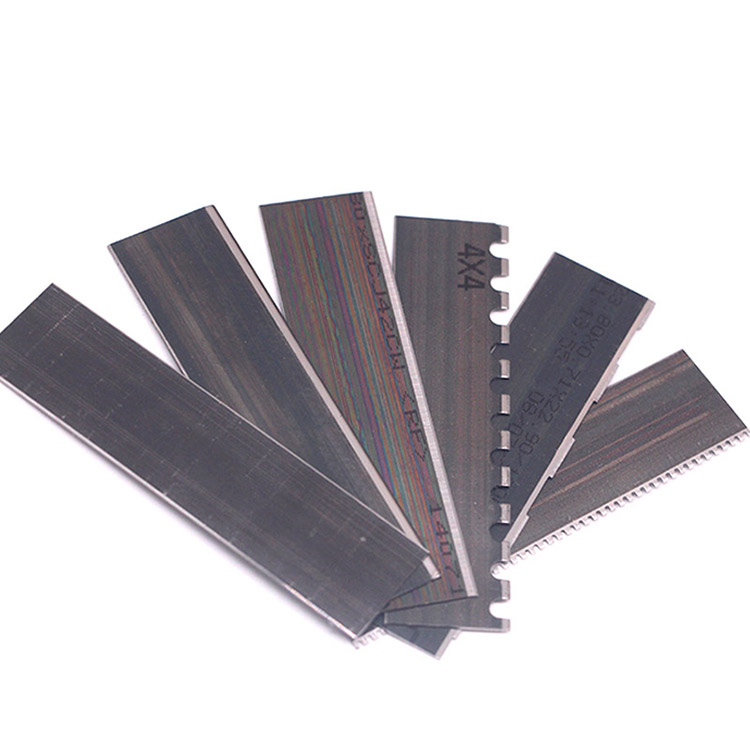

- Steel rule thickness: 0.45 / 0.71 / 1.07 mm

- Steel rule height: 7–32 mm

- Compatible rules: Cutting, creasing, perforation, broaching, nicking, hole punching (optional)

With a flexible configuration, this auto bending machine for die cutting supports the needs of packaging, printing, and die-making workshops.

Key Advantages of the YTB30 Serie Auto Bender Machine

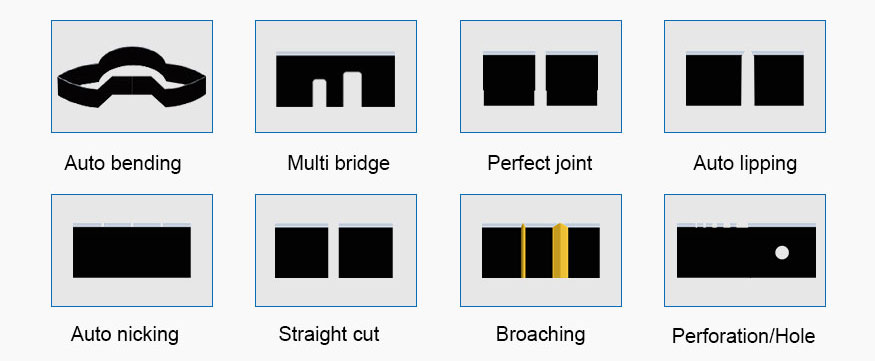

1. Multi-Functional Punching System

The machine supports multiple bending and punching operations in one structure:

- Cutting

- Lipping

- Perforation

- Broaching

- Notching

This greatly improves productivity and reduces tool change time.

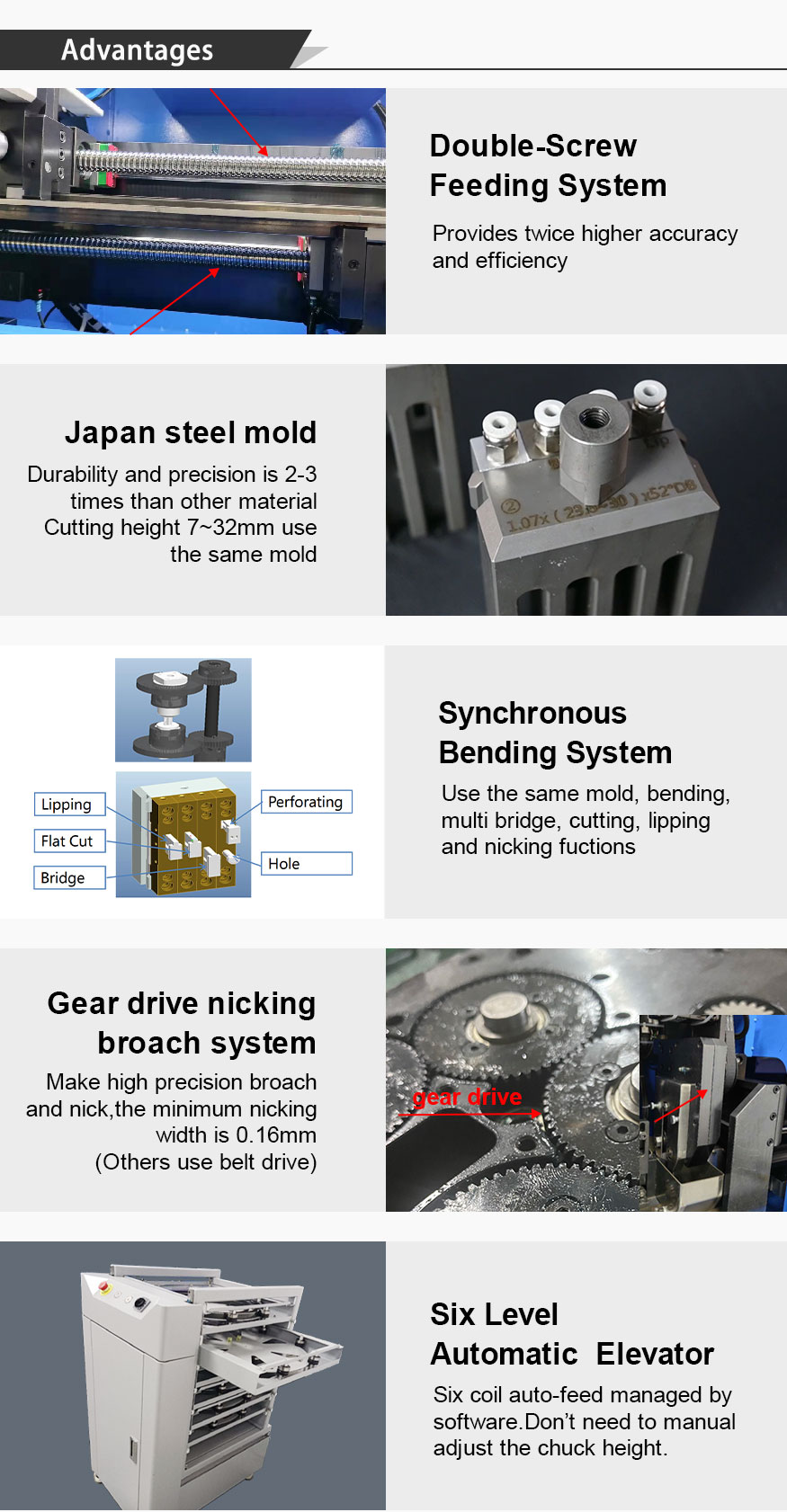

2. Patented Dual-Screw Feeding System

The double-screw structure ensures stable rule feeding and supports 7–32 mm rule height using the same mold.

Result:

- Faster feeding

- Greater precision

- More reliable long-run performance

3. Top-Mounted Broaching Unit

Designed for convenient blade replacement and easy maintenance:

- Smooth chip removal

- Clean working environment

- Reduced downtime

4. Full-Servo System (High Stability & Low Energy Use)

The machine uses a complete servo drive platform to deliver:

- Accurate rule forming

- Lower energy consumption

- Stable bending results

- Easy maintenance

5. Optional Tungsten Nicking Tool

For users needing high-speed and long-lifespan nicking performance:

- Size range: 0.18–1.0 mm

- Extremely durable

- Clean and consistent nicking lines

6. Easy Parts Replacement & Maintenance

The modular design of this auto bender machine China ensures quicker part changes and reduced machine downtime.

Technical Parameters

| Specification | Details |

|---|---|

| Rule Thickness | 0.45 / 0.71 / 1.07 mm |

| Rule Height | 7–32 mm |

| Bridge Width | >3 mm (customized available) |

| Bridge Height | 10–20 mm |

| Air Supply | 1 CFM @ 6 Bar |

| Power Supply | 220V Single-Phase, 20A, 3kW, 50/60Hz |

| Machine Weight | 420 kg |

| Machine Size | 2800 × 800 × 1500 mm |

| Packaging | Wooden case |

Functions & Usage

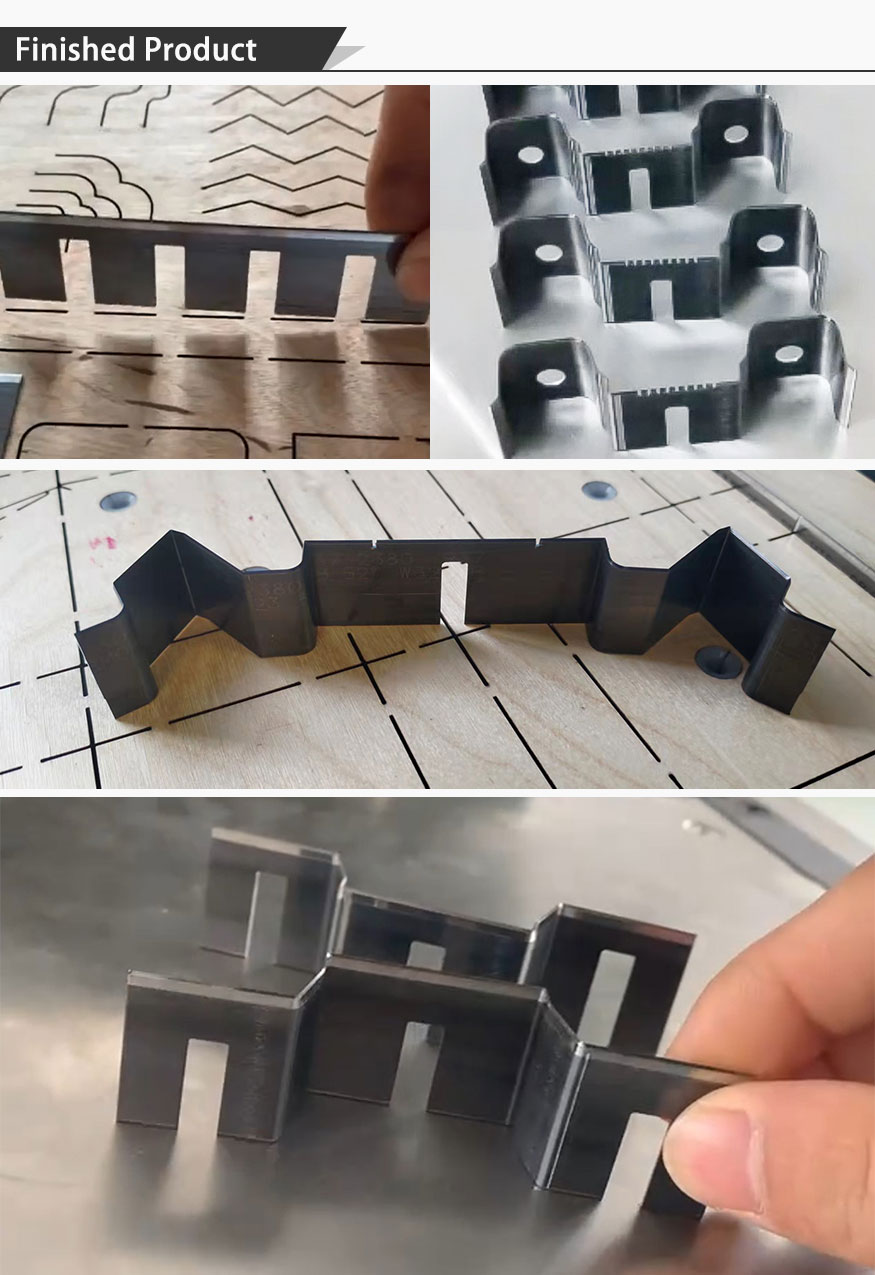

Perfect Joint Forming

Accurate bending ensures seamless rule joints.

Auto Lipping & Punching

Supports auto lipping, punching, straight cutting, and once-cut operations.

Auto Bridge Creation

10–20 mm bridge punching for fast die assembly.

Minimum Bending Length: 2 mm

Ideal for detailed structures and complex shapes.

Dual-Screw Automatic Feeding

Smooth and stable steel rule feeding.

Six-Coil Auto Feeding System

Enables efficient multi-rule processing.

This makes it one of the most powerful auto bending machines for sale in the market for professional diemakers.

Our Services

- English-speaking engineers for installation & training

- One-stop die making supply: machines + tools + consumables

- English software + manuals + training videos

- Fast service & low maintenance cost

- 1-year warranty + lifetime engineering support

Before Quoting, Please Tell Us:

- Which machine models you need

- Materials & rule specifications

- Your business type (end user, die maker, distributor)

Contact YITAI Today

As a trusted auto bender machine factory, YITAI manufactures durable, high-precision equipment for global die-making workshops.

If you’re looking for a reliable auto bending machine for die cutting or want to find a professional auto bending machine for sale, our team will help you choose the ideal setup for your production needs.