How Flat Die Quality Impacts Die-Cutting Accuracy and Efficiency

The quality of your flat die has a big impact on how well your cutting works. A good die makes your work faster, more accurate, and less wasteful.

Here’s what matters most:

1. Blade Sharpness

- Why it matters: Sharp blades cut cleanly. Dull blades tear or drag the material.

- Effect: Clean cuts, less scrap, less pressure needed, better results.

2. Material Alignment & Registration

- Why it matters: The die must match the material perfectly. Misalignment wastes material.

- Effect: Accurate cuts, every time, on every sheet.

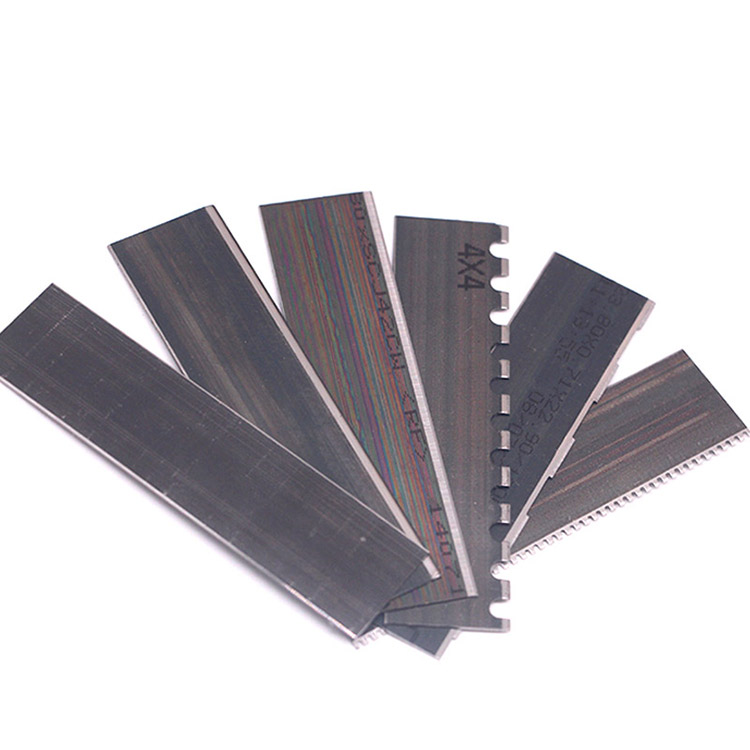

3. Die Material Quality

- Why it matters: Strong, durable materials last longer and cut consistently. Cheap materials wear out fast.

- Effect: Long-lasting performance, fewer replacements, steady quality.

4. Rule Height Consistency

- Why it matters: Uneven blade heights cause partial or uneven cuts.

- Effect: Uniform pressure, complete cuts, no mistakes.

5. Ejection System Quality

- Why it matters: Foam or rubber helps remove cut parts. Poor ejection causes jams or incomplete cuts.

- Effect: Smooth workflow, less manual work, less downtime.

6. Tolerance & Dimensional Accuracy

- Why it matters: Tight tolerances are critical for detailed or layered designs. Loose tolerances cause mistakes.

- Effect: Parts match design perfectly, less scrap, less rework.

7. Maintenance & Wear Resistance

- Why it matters: Worn or damaged dies produce defects.

- Effect: Easy maintenance, longer sharpness, consistent cutting quality.

Quick Tips for Operators

- Always check blade sharpness before production.

- Align material carefully to the die.

- Inspect dies for wear and damage regularly.

- Keep ejection systems clean and working.

- Use high-quality dies to save time, material, and effort.

Conclusion

Good flat dies mean faster production, cleaner cuts, less waste, and more satisfied customers. Investing in quality dies pays off in the long run.