Which One Is Right for Your Plywood Processing Business?

When investing in new equipment, many manufacturers ask:

“Both CNC routers and laser cutting machines can cut boards — what’s the real difference, and which one should we choose?”

This is a critical decision. Although both machines are used for cutting, their working principles, suitable materials, cost structures, and production roles are completely different. Choosing the wrong machine can lead to wasted investment, low productivity, or unnecessary operating costs.

Below, we answer the most common customer questions to help you choose the right equipment based on real production needs.

Q1: What Is the Fundamental Difference Between a CNC Router and a Laser Cutting Machine?

The essential difference lies in the cutting method.

CNC Router

A CNC router uses a high-speed rotating cutting tool or saw blade to mechanically remove material.

This is a contact cutting process with strong mechanical force and stable performance for thick boards.

CNC Router

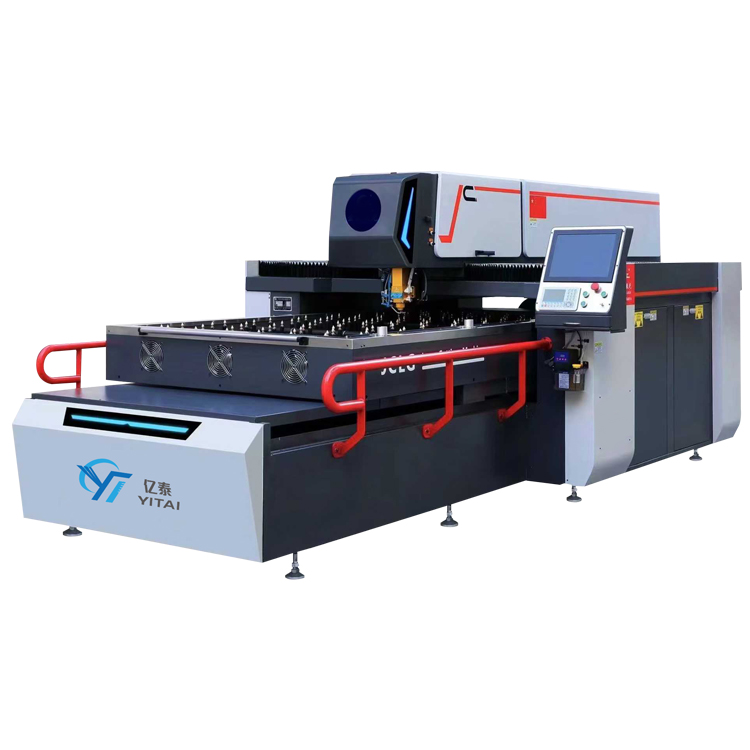

Laser Cutting Machine

A laser cutting machine uses a high-energy laser beam to melt or vaporize material.

This is a non-contact thermal cutting process that excels at fine details and thin materials.

This difference determines their performance in cutting speed, material compatibility, edge finish, and running costs.ence determines their speed, material compatibility, edge quality, and operating cost.

Die Board Laser Cutting Machine

Q2: Which machine is better for cutting plywood and wooden panels?

For plywood, MDF, particle board, and furniture panels, a CNC router is the more suitable and economical solution.

Why?

- Designed specifically for wood-based panels

- Handles thick boards efficiently

- Supports continuous, high-volume cutting

- Lower operating cost per sheet

Laser machines are generally not ideal for thick wood panels because:

- Burning and charring may occur

- Cutting speed decreases significantly with thickness

- Operating cost is higher

Conclusion: For panel furniture and plywood processing, CNC routers are the industry standard.

Q3: When should I consider a laser cutting machine instead?

Laser cutting machines excel when precision and material type demand it.

They are ideal for:

- Stainless steel, carbon steel, and aluminum sheets

- Acrylic and thin plastics

- Complex shapes and intricate patterns

- Applications where smooth, finished edges are required without secondary processing

If your production focuses on metal fabrication, signage, or decorative cutting, a laser machine is often the better choice.

Q4: Which machine provides better cutting quality?

It depends on how you define “quality.”

| Requirement | Better Choice | Reason |

|---|---|---|

| Fast, straight panel sizing | CNC Router | High speed and structural stability |

| Smooth edge with minimal mechanical marks | Laser Cutting Machine | Non-contact thermal cutting leaves fine edges |

| Complex shapes and small details | Laser Cutting Machine | No tool radius limitation |

| Thick wooden board cutting | CNC Router | Strong mechanical cutting force |

For most plywood applications, saw marks from CNC routers are acceptable because edges are often laminated, edge-banded, or further processed.

Q5: Which machine is faster for large-volume production?

For batch processing of standard-sized panels, CNC routers are significantly faster.

Reasons:

- Designed for continuous mechanical cutting

- No thermal buildup limitations

- Suitable for thick boards and repeated operations

Laser cutting speed decreases as material thickness increases, making it less efficient for bulk panel processing.

Q6: How do investment and operating costs compare?

Cost is often a deciding factor.

CNC Router

- Lower initial investment

- Lower power consumption

- Simple maintenance

- Tooling (bits/blades) is affordable

Laser Cutting Machine

- Higher purchase price

- Higher energy consumption

- Requires cooling systems and gas supply

- More complex maintenance

For factories focused on cost control and stable mass production, CNC routers usually offer a better return on investment.

Q7: Can these two machines replace each other?

In most professional factories, they are complementary, not substitutes.

Typical production setup:

- CNC router handles panel sizing and structural cutting

- Laser cutting machine handles precision parts, metal components, or decorative elements

Each machine performs best in its own field.

Q8: Which machine is better for small, intricate designs?

Laser cutting machines have an advantage in:

- Fine patterns

- Small holes

- Sharp internal corners

Because the laser beam has no physical tool diameter, it can achieve details that mechanical tools cannot.

Q9: Which one is easier to operate and maintain?

CNC routers generally:

- Have simpler mechanical structures

- Are easier for woodworking operators to learn

- Require standard maintenance procedures

Laser cutting machines require:

- Knowledge of optics and laser systems

- Gas management

- Cooling system maintenance

Operational complexity is typically higher for laser systems.

Q10: How should I choose the right machine for my factory?

Ask yourself three practical questions:

- What materials do I process most?

Wood panels → CNC router

Metal or acrylic → Laser cutting - What matters more: speed or precision finish?

High output → CNC router

Fine detail → Laser cutting - What is my long-term production plan?

Furniture and panel processing → CNC router

Diversified fabrication → Consider both

Final Thoughts

There is no “better” machine in absolute terms — only the machine that best matches your materials, production structure, and business goals.

Choosing the right equipment leads to:

- Higher productivity

- Lower operating cost

- More reliable delivery

Before investing, it is always advisable to evaluate your material mix, order types, and future production direction.